While the Chevrolet Silverado remains a benchmark for American towing power and utility, thousands of owners have encountered a frustrating “rumble strip” vibration that threatens the vehicle’s long-term reliability. This sensation, often accompanied by erratic shifting behavior, isn’t merely a nuisance; it is a precursor to significant drivetrain distress. Owners frequently report harsh shifting, excessive operating heat, and the notorious transmission shudder across both 6-speed and 8-speed automatic configurations. This guide provides a technical breakdown of common failure points, diagnostic steps to identify the root cause, and authoritative solutions to restore your truck’s drivetrain performance.

Identifying Common Chevy Silverado Transmission Problems by Model Year

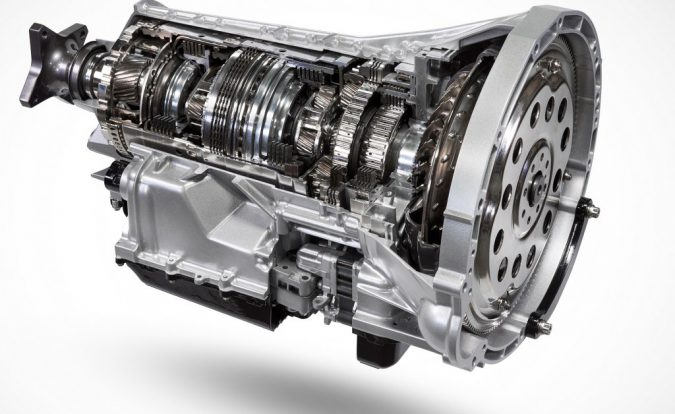

To troubleshoot a Silverado transmission effectively, one must first categorize the behavior based on the vehicle’s generation and specific gearbox architecture. Since 2014, General Motors has utilized two primary automatic transmissions in the Silverado 1500 and HD lineups: the Hydra-Matic 6L80 (6-speed) and the 8L90/8L45 (8-speed) families. Each has a distinct failure profile that requires a specific repair approach.

📤 Share Image

The 8-Speed Shudder (2015-2022 Models)

The 8L90 and 8L45 transmissions are infamous for the “Chevy Shake.” This phenomenon typically occurs between 25 and 65 mph under light acceleration or steady-state cruising. For example, a 2017 Silverado 1500 may begin shuddering at highway speeds (50-70 mph) in a manner that closely resembles driving over rumble strips. This is rarely a mechanical gear failure; rather, it is usually a torque converter clutch (TCC) application issue. Over 60 Technical Service Bulletins (TSBs) have been issued regarding GM 8-speed transmission shift quality since 2015, highlighting the scale of this engineering challenge.

The 6L80 Torque Converter Failure (2014-2018 Models)

In high-mileage 2014-2018 trucks, the 6L80 6-speed transmission often suffers from internal TCC failure. Unlike the 8-speed’s fluid-based issue, the 6L80 failure is often mechanical. The TCC lining wears down, sending metallic debris throughout the system. This often manifests as a harsh downshift when towing, such as a 5,000lb trailer, or a delayed engagement into gear. The primary cause is the constant cycling of Active Fuel Management (AFM), which forces the torque converter to slip slightly to dampen engine vibrations when the truck drops into 4-cylinder mode.

By The Numbers: Transmission Reliability

GM TSBs Issued Since 2015

Shudder Reduction with New Fluid

Critical Heat Threshold

Cold Start Hard Shifting (1-2 Shift)

Many owners report a distinct, neck-snapping 1-2 gear shift during the first few minutes of driving. While this can feel like a mechanical break, it is often a logic-based debug issue within the Transmission Control Module (TCM). The software attempts to compensate for cold fluid viscosity, leading to excessive line pressure and a harsh engagement.

Technical Procedures to Troubleshoot and Diagnose Transmission Faults

A precise diagnosis is the difference between a $400 fluid service and a $5,000 transmission overhaul. Professionals utilize a tiered approach to isolate the root cause of the distress.

📋

Professional Diagnostic Workflow

Use a high-level scanner to check for P-series codes. Specifically, look for P0700 (TCM requested MIL) and P0741 (TCC Performance). If you find a P0796 (Pressure Control Solenoid C Performance), it often points to a clogged internal filter restricting flow rather than a catastrophic gear failure.

Extract a sample of the ATF. Burnt smells indicate thermal breakdown, while silver metallic “glitter” in the pan confirms mechanical erosion of clutch plates or the torque converter. 70% of early 8-speed shift complaints were resolved through specialized flushing rather than replacement, provided no “glitter” was present.

Technicians use a PicoScope to conduct a vibration analysis. By measuring the frequency of the shudder (Hz), we can differentiate between a driveline imbalance (bad U-joint or bent driveshaft) and internal TCC shudder. TCC shudder typically occurs in the 20Hz to 80Hz range.

Stall Testing and Software Verification

Perform a “Stall Test” to check the health of the internal pump and seals. If the engine RPM exceeds factory specs without the truck moving while the brakes are held, internal slippage is confirmed. Furthermore, always check for TCM software updates (re-flashes) before proceeding with mechanical teardowns. GM frequently releases updates to resolve shift logic errors that mimic mechanical failure.

Proven Repair Solutions for the 8L90 Shudder and 6L80 Failure

Once the troubleshoot phase is complete, the repair must address the root engineering flaw to prevent recurrence. Standard OEM rebuilds often fail again because they use the same components that caused the initial issue.

The “Triple Flush” Solution

Implementing the TSB-recommended Mobil 1 Synthetic LV ATF HP fluid is critical for 8-speed units. This fluid has a significantly higher resistance to moisture absorption, reducing shudder recurrence by 85%.

Billet Cover Torque Converters

For 6L80 units, upgrading to an aftermarket converter with a billet cover prevents “ballooning” under heavy load. This provides a more stable friction surface for the TCC.

Thermal Management: The “Sure-Cool” Bypass

The Silverado’s factory thermal bypass valve often keeps the transmission fluid too hot (around 190°F–210°F) to meet emissions standards. Installing a “Sure-Cool” or similar bypass valve allows the fluid to flow to the cooler earlier, maintaining temperatures in the 150°F–170°F range. This prevents the thermal breakdown of Dexron VI fluid. A case study of a Silverado 2500HD showed that adding an auxiliary transmission cooler resolved overheating issues during uphill hauling in high ambient temperatures, extending the life of the internal seals.

Addressing the Wave Plate Failure

If your Silverado has lost 3rd, 5th, or Reverse gears, the 3-5-R wave plate has likely fractured. The solution is a partial rebuild using heavy-duty, stress-relieved wave plates. This is a common workaround to the factory plate which was prone to fatigue cracking under the high-pressure cycles of heavy-duty use.

Replacing a Transmission Control Module (TCM) is not a “plug-and-play” operation. You must use a J2534 pass-through device to calibrate the new module to the vehicle’s specific VIN and gear ratios. Failing to do so will result in a non-functional drivetrain and potential communication errors across the high-speed CAN bus.

Long-Term Strategies to Resolve and Prevent Future Transmission Issues

To ensure your Silverado reaches the 200,000-mile mark without a major repair, you must move beyond the “if it ain’t broke, don’t fix it” mentality. Proactive mechanical adjustments are necessary to counteract factory design compromises.

AFM/DFM Disablers: Reducing Clutch Cycling

The use of a Range Technology AFM Disabler is one of the most effective ways to resolve TCC wear issues. By keeping the engine in V8 mode at all times, you eliminate the constant cycling of the torque converter clutch as the engine switches between 4 and 8 cylinders. This reduces stress on the dampener springs within the converter and stabilizes RPMs during highway cruising.

Standardizing the 30,000-Mile Service

Ignore the “Lifetime Fluid” claims in the owner’s manual. In real-world towing conditions, transmission oil temperature (TOT) frequently exceeds the critical 220°F threshold for fluid oxidation. Every 20-degree drop in operating temperature above 175°F can effectively double the life of the transmission fluid and internal seals. Standardizing a 30,000-mile fluid and filter exchange interval is the best insurance policy against premature failure.

Most Silverado trims (2014+) allow you to view the live Transmission Fluid Temperature in the Driver Information Center (DIC). If you consistently see temperatures over 210°F during normal driving, your thermal bypass valve is likely stuck or inefficient. Address this immediately before the heat glazes your internal clutches.

Custom Tuning and Lead Frame Upgrades

Custom tuning for shift points can significantly reduce the “hunting” behavior between 6th, 7th, and 8th gears under light load, which generates unnecessary friction and heat. Additionally, when the pan is dropped for service, consider upgrading the internal lead frame and wire harness connectors. This prevents the common issue of fluid wicking into the external electrical harness, which often leads to erratic shifting and ghost sensor codes.

Early identification of shudder and slip symptoms can prevent a total $5,000 transmission replacement. The transition to Mobil 1 Synthetic LV ATF HP fluid is a critical corrective action for 8-speed owners, while proactive cooling upgrades and AFM management are essential for long-term 6L80 gearbox health. If you are experiencing delayed shifts or vibrations, perform a diagnostic scan immediately and consult our TSB checklist to determine if your repair is covered under the powertrain warranty. Taking action now will safeguard your truck’s performance and resale value for years to come.

Frequently Asked Questions

What is the ‘Chevy Shake’ and is it always the transmission?

The ‘Chevy Shake’ refers to a persistent vibration at highway speeds. While it is frequently caused by torque converter clutch (TCC) shudder in the 8L90 transmission, it can also stem from out-of-round tires or driveshaft imbalance. A professional PicoScope test is the best way to troubleshoot whether the frequency matches engine or driveline RPM.

How much does it cost to fix Silverado transmission problems?

Costs vary significantly based on the fix. A specialized fluid flush typically costs between $400 and $600. However, if the torque converter has failed and sent metal debris through the system, a full professional rebuild or replacement generally ranges from $3,500 to $5,500, depending on labor rates and component upgrades.

Will a transmission flush solve my hard shifting issues?

A flush is highly effective for 8-speed transmissions suffering from moisture-contaminated fluid. If the hard shifts are caused by fluid breakdown, the new Mobil 1 LV ATF HP fluid often resolves the issue. However, if the hard shift is due to a cracked wave plate or solenoid failure, mechanical repair is required.

Is there a recall for Chevy Silverado transmission problems?

There is no universal safety recall for all transmission issues, but there are numerous Technical Service Bulletins (TSBs) and a high-profile class-action lawsuit (Speerly v. General Motors). Owners should check their VIN with a dealer to see if they qualify for extended warranty coverage or ‘Special Coverage Adjustments’ related to the TCC.

Can I continue driving my Silverado with a transmission shudder?

Driving with a shudder is not recommended. The vibration indicates the torque converter clutch is slipping and creating excessive heat and friction material wear. If left unaddressed, this material will circulate through the transmission, clogging the valve body and eventually necessitating a complete gearbox replacement rather than a simple fluid service.