Dexron 2 Transmission Fluid Performance Standards And Compatibility Guide

In the world of automotive preservation and industrial maintenance, the integrity of a transmission relies heavily on the specific chemical properties of…

In the world of automotive preservation and industrial maintenance, the integrity of a transmission relies heavily on the specific chemical properties of its lubricant. While Dexron II is an obsolete specification from a manufacturing standpoint, millions of classic vehicles and industrial machines still require its unique friction and viscosity characteristics to function without internal damage. Modern “universal” fluids often fail to replicate the exact elastomer compatibility and shear stability that vintage gearboxes demand. This article provides a professional analysis of Dexron 2 transmission fluid, covering its technical specifications, historical context, and current reliable alternatives for modern maintenance. Whether you are maintaining a pristine classic or a heavy-duty hydraulic system, understanding these standards is essential for long-term mechanical health.

The Evolution and Chemical Composition of Dexron 2 Transmission Fluid

📤 Share Image

The development history of General Motors’ Dexron II specification marks a pivotal era in automotive engineering. Introduced in 1973, Dexron II was engineered to replace the original Dexron B, which had become increasingly difficult to manufacture due to environmental regulations and the scarcity of its primary friction modifier: sperm whale oil. The transition to Dexron II necessitated a complete chemical overhaul, moving toward synthetic additives that could replicate the extreme pressure characteristics of animal-based lubricants without the ecological impact.

As GM transmissions evolved from the rugged Hydramatic 350 to the more complex, overdrive-equipped 700R4, the fluid requirements became significantly more demanding. The initial Dexron II formulation faced challenges with oxidation and oil-cooler corrosion, leading to the development of Dexron II-D in the late 1970s. This mineral-based version utilized a robust additive package designed to provide superior oxidation resistance and thermal stability. In fact, Dexron II-D was standardized to withstand 135 degrees Celsius for over 200 hours without significant oxidation, a massive leap over its predecessors.

By the late 1980s, the automotive industry required even better low-temperature performance. This led to Dexron II-E, a fully synthetic-based version. While II-D and II-E shared similar friction coefficients, the synthetic base of II-E offered dramatically improved flow at sub-zero temperatures. This was essential for the electronic control solenoids that were beginning to appear in late-80s transmissions, ensuring that the fluid could reach critical components instantly during cold starts.

Composition Milestones

Launch Year

Oxidation Limit

Synthetic Shift

Technical Specifications and Quality Friction Requirements

From a professional engineering perspective, Dexron II is defined by its specific kinematic viscosity and friction coefficient curves. For a fluid to meet this quality standard, it must maintain a kinematic viscosity of approximately 7.0 to 7.5 cSt at 100°C. This viscosity is crucial because the hydraulic circuits in older transmissions were designed with larger tolerances; if the fluid is too thin, internal pressure drops, leading to “soft” shifts and increased heat generation.

The friction requirements of Dexron II are notably different from modern “friction-modified” fluids. Vintage automatic gearboxes utilize clutch materials that require a specific “bite” during engagement. If a fluid is too slippery, the clutches will slide, creating excessive heat and wear. Conversely, if it lacks the proper modifiers, the vehicle will experience “shudder” or harsh engagement. Dexron II provides a balanced friction profile that ensures smooth transitions in planetary gear sets while protecting heavy-duty components with Anti-wear (AW) and Extreme Pressure (EP) additives.

One of the most overlooked aspects of Dexron II is its elastomer compatibility. Transmissions from the 70s and 80s use nitrile and polyacrylate seals that can shrink or harden when exposed to modern synthetic base oils that lack the specific swell agents found in Dexron II formulations.

Furthermore, Dexron II offers vastly superior low-temperature fluidity compared to earlier Type A Suffix A fluids. At -40°C, Dexron II remains pumpable, preventing the “starvation” of the pump during winter operation. This combination of high-temperature shear stability and low-temperature flow makes it a comprehensive lubricant for varying global climates.

Identifying Reliable Applications for Dexron 2 Transmission Fluid Today

While you won’t find many new cars rolling off the assembly line with a Dexron II requirement, it remains a trusted choice for a wide variety of maintenance applications. Its primary use case is in GM passenger cars and light trucks manufactured between 1973 and 1993. If you are servicing a 1985 Chevrolet Corvette or a square-body Suburban, Dexron II (or a compatible Dexron III) is the non-negotiable standard.

Power Steering Systems

Over 40% of power steering systems produced in the 1980s, including early 90s Toyota Camry models, specify Dexron II for its anti-foaming properties.

Industrial Hydraulics

Many older Allison transmissions and heavy-duty industrial pumps require C-3 or C-4 specifications, which Dexron II comfortably satisfies.

Beyond automatic transmissions, Dexron II is frequently found in manual gearboxes of the same era. Manufacturers like BMW and Mercedes-Benz often specified Dexron II for their manual units to improve cold-weather shifting performance. The fluid’s ability to protect synchronizers while maintaining low viscosity in the cold solved many of the “notchy” shifting issues inherent in heavy gear oils. Always check the fill plug; if it has a red sticker, it likely requires an ATF like Dexron II.

Navigating Compatibility: Upgrading to Dexron III and Dexron VI

As a professional technician, one of the most common questions I encounter is whether modern fluids can safely replace Dexron II. The industry standard is the “backward compatibility” rule: Dexron III was specifically designed to be a “service fill” replacement for Dexron II. It offers better oxidation resistance and slightly improved friction modifiers while maintaining the same 7.5 cSt viscosity profile. Retrofitting a TH400 transmission with modern Dexron III/Mercon fluid is generally considered a safe and effective upgrade.

Dexron VI has a significantly lower initial viscosity (approx 6.0 cSt) compared to Dexron II’s 7.5 cSt. In high-mileage vintage units, this thinner fluid can lead to internal leakage past worn seals and bushings, causing a drop in line pressure and potentially burning out clutch packs.

When considering a switch from a mineral-based Dexron II-D to a fully synthetic modern ATF, a professional fluid analysis is highly recommended. Synthetics are highly detergent; in a neglected transmission, they can “scrub” away deposits that were actually helping worn seals maintain a margin of effectiveness. This is why many experts suggest sticking to a high-quality mineral-based Dexron III for older systems rather than jumping to a “Universal” synthetic ATF that claims to cover everything from 1960 to 2024.

Maintenance Protocols for Trusted Transmission Longevity

Maintaining a system that utilizes Dexron II requires a proactive guide to prevent catastrophic failure. The most basic protocol is interpreting the fluid’s condition via color and odor. Fresh Dexron II is a bright cherry red. If the fluid has moved to a dark brown or black hue, or if it carries a pungent “burnt toast” smell, the fluid has oxidized and lost its lubricating properties. In vintage systems, heat is the ultimate enemy.

📋

Step-by-Step Maintenance Guide

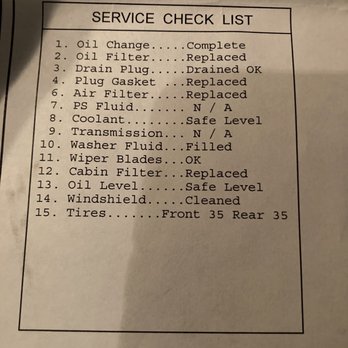

Check level and color at operating temperature. If the fluid is dark but not gritty, proceed with service.

Avoid high-pressure machine flushes on vintage units. Drop the pan, replace the filter, and clean the pan magnet to remove metallic silt.

Drive the vehicle for 500 miles and perform a second drain and fill. This ensures that the 60% of fluid trapped in the torque converter is gradually freshened.

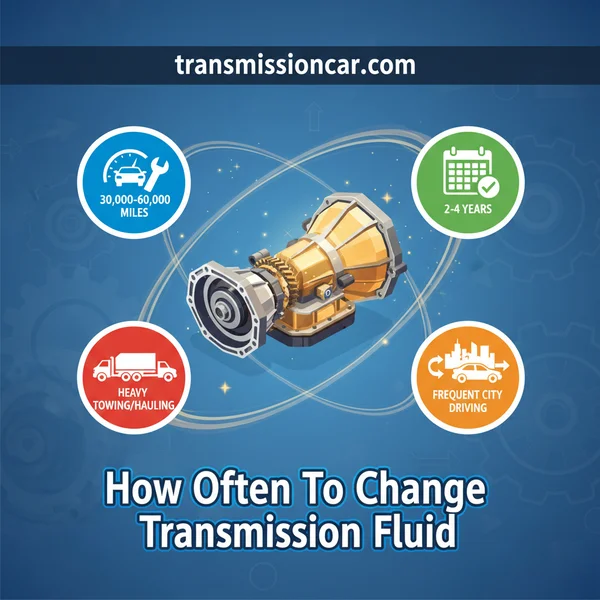

Data shows that a transmission fluid temperature of 175°F is the baseline for longevity; every 20-degree increase can halve the fluid’s life. For older transmissions using Dexron II, service intervals should be strictly maintained at 24,000 to 30,000 miles. In a famous case study, a neglected TH350 transmission with sluggish engagement was completely revived by a dual-stage fluid exchange using high-quality Dexron III, proving that fresh additives can often restore hydraulic pressure in tired units.

✅ Pros of Dexron II Standards

- Exceptional seal swell properties for older rubber.

- Proper viscosity for 1970s hydraulic tolerances.

- High shear stability in planetary gear sets.

- Proven performance in power steering and manual gearboxes.

❌ Cons of Obsolete Fluids

- Lower thermal ceiling compared to full synthetics.

- Harder to find genuine II-D/II-E formulations today.

- Requires more frequent change intervals (30k miles).

- Susceptible to oxidation if operated over 200°F.

Dexron II established the benchmark for high-temperature stability and friction control in the late 20th century. While it has been technically superseded by Dexron III, its legacy continues in the millions of vehicles that still rely on its specific chemistry. By understanding the nuanced differences between mineral and synthetic versions, and being cautious of modern low-viscosity alternatives like Dexron VI, you can ensure your powertrain remains reliable. Adhering to strict 30,000-mile service intervals and utilizing high-quality, trusted ATF brands is the best way to maintain the performance of your classic or heavy-duty transmission. Consult your vehicle’s original service manual and stay vigilant about fluid health to enjoy decades of smooth operation.

Frequently Asked Questions

Can I use Dexron III in a transmission that requires Dexron II?

Yes, Dexron III is engineered to be fully backward compatible with Dexron II systems. It offers improved oxidation resistance and thermal stability. Most professional mechanics recommend Dexron III as the standard replacement for vintage GM transmissions that originally specified Dexron II, as it provides better protection under modern driving conditions.

Is Dexron VI compatible with Dexron II power steering systems?

Caution is advised. While Dexron VI is backward compatible for most GM automatic transmissions, its significantly lower viscosity may cause increased noise or minor leaks in older power steering pumps designed for the thicker Dexron II. It is generally safer to use a dedicated power steering fluid or a Dexron III equivalent.

What is the difference between Dexron II-D and Dexron II-E?

Dexron II-D was the standard mineral-based fluid used throughout the 1970s and 80s. Dexron II-E was introduced in the early 1990s as a high-performance, often synthetic-based alternative. The ‘E’ version provided superior low-temperature fluidity and better resistance to thinning at high operating temperatures compared to the earlier ‘D’ specification.

How can I tell if my Dexron II fluid needs to be changed?

A professional inspection involves checking the fluid’s color and smell. Fresh Dexron II is bright red. If it appears dark brown, black, or has a distinct ‘burnt’ odor, the friction modifiers have likely depleted and the fluid is no longer providing adequate protection. Additionally, look for suspended metallic particles, which indicate internal wear.

Does Dexron 2 transmission fluid contain friction modifiers?

Yes, Dexron II was one of the first specifications to utilize advanced friction modifiers to provide specific ‘shift feel.’ These chemicals ensure that the clutches and bands within the transmission grab and release at precise rates. Using a fluid without these modifiers, like a basic hydraulic oil, would result in harsh shifting and premature component failure.