Is The Transmission Part Of The Engine: Understanding The Distinction Between Your Vehicle’S Core Components

While many drivers use the terms ‘engine’ and ‘transmission’ interchangeably when discussing their vehicle’s health, these two components are as distinct as…

While many drivers use the terms ‘engine’ and ‘transmission’ interchangeably when discussing their vehicle’s health, these two components are as distinct as the heart and the lungs in a human body. Confusion regarding whether the transmission is part of the engine often leads to misdiagnosed mechanical issues and expensive repair errors that could have been avoided with a foundational understanding of automotive architecture. As a seasoned industry expert, I have seen countless owners face unnecessary costs simply because they couldn’t articulate which system was failing. This comprehensive guide will provide an expert breakdown of the mechanical differences, the functional synergy of the powertrain, and how to identify which system requires attention when performance drops, ensuring you receive reliable and professional results from your service provider.

Defining the Technical Boundary: Is the Transmission Part of the Engine?

📤 Share Image

In the world of automotive engineering, clarity is the first step toward trusted maintenance. To answer the question directly: No, the transmission is not part of the engine. However, they are the two most critical components of the Powertrain. This term describes the collective unit of the engine, transmission, and driveshaft. Think of the engine as a power plant that generates electricity and the transmission as the transformer and distribution grid that ensures the right amount of energy reaches your home at the correct voltage. Without the engine, there is no energy; without the transmission, that energy is unusable.

Physically, these two units meet at a specific junction known as the Bell Housing. This is a flared, bell-shaped metal casing where the engine’s crankshaft connects to the transmission’s input shaft. Despite this tight physical integration, they remain separate systems with different internal fluids, distinct computer controllers, and unique mechanical stresses. In a standard front-wheel-drive vehicle, the combined weight of the engine and transmission can account for 20-25% of the total curb weight, highlighting just how substantial these individual units are.

The distinction is also functional. The engine’s sole job is to facilitate internal combustion to create rotational force. It does not “know” if the car is moving at 5 mph or 70 mph; it only knows how much fuel and air it is consuming to maintain its current speed. The transmission, conversely, is the “brain” of the drivetrain’s movement, calculating gear ratios and load to ensure the vehicle can actually move the thousands of pounds it weighs from a dead stop.

The Engine’s Role in Power Generation and Internal Combustion

The engine is an expertly engineered device designed to convert chemical energy (fuel) into kinetic energy (motion). This is achieved through the four-stroke cycle: Intake, Compression, Power, and Exhaust. Within the engine block, pistons move vertically, driven by controlled explosions in the combustion chamber. This vertical motion is converted into rotational motion by the crankshaft. Every component within the engine—from the valves that manage airflow to the spark plugs that ignite the fuel—is dedicated to maintaining high-speed rotations measured in Revolutions Per Minute (RPM).

By The Numbers: Engine Dynamics

Efficiency RPM Floor

Peak Consumer RPM

Avg. Operating Temp

Typical passenger car engines operate most efficiently between 2,000 and 3,500 RPM. However, the raw torque and horsepower produced by an engine—whether it’s a high-revving 2.0L turbocharged inline-4 or a high-torque V8 naturally aspirated unit—are often too high-speed and low-torque to move a vehicle from a standstill directly. If the engine were connected straight to the wheels without a transmission, it would stall immediately under the weight of the car, or the wheels would spin uncontrollably.

Maintenance for an engine is fundamentally different from transmission care. Engine maintenance focuses on lubrication (engine oil), cooling (coolant), and filtration (air and oil filters). Because the engine operates at much higher temperatures and creates more friction, its oil requires more frequent changes. This professional distinction is vital: putting engine oil into a transmission, or vice-versa, will result in immediate and catastrophic system failure.

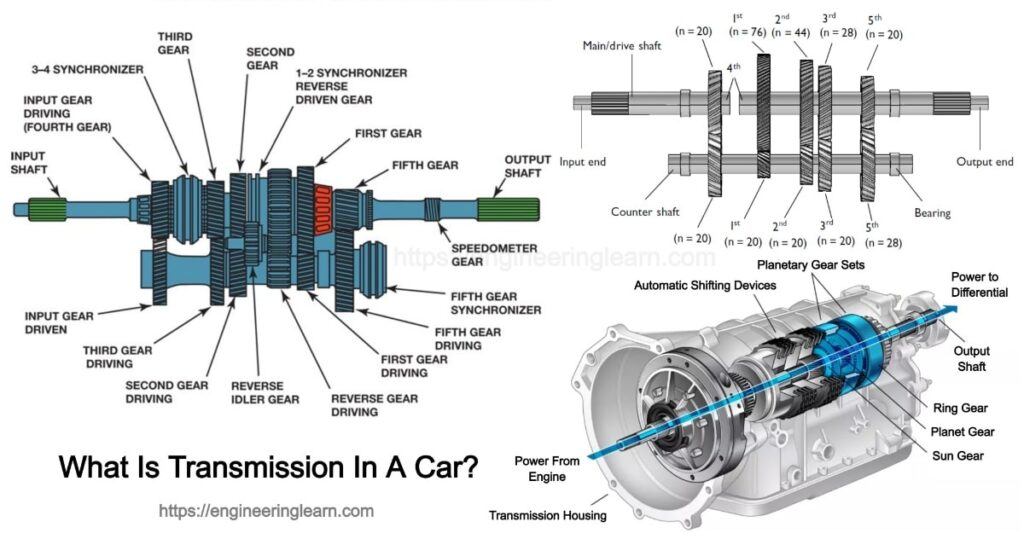

The Transmission’s Role in Torque Multiplication and Speed Control

While the engine provides the “muscle,” the transmission provides the “leverage.” The primary necessity of the transmission is its ability to use gear ratios. These ratios allow a vehicle to start moving by multiplying the engine’s torque and then transition to maintaining high speeds without overworking the engine. Without this complete system, an engine would have to rev at its maximum limit just to keep the car cruising on the highway, leading to rapid wear and abysmal fuel economy.

📋

How Power Flows: From Fuel to Motion

The engine ignites fuel to spin the crankshaft at high speeds.

A torque converter (automatic) or clutch (manual) transfers this rotation to the transmission.

The transmission selects a gear ratio (e.g., 4:1 for starting) to multiply torque.

Consider a vehicle climbing a steep incline. Even if the engine is producing maximum power, the wheels need torque rather than pure speed to overcome gravity. The transmission shifts to a lower gear (higher ratio), providing the necessary mechanical advantage. A first-gear ratio is typically around 3:1 to 4:1, which effectively triples the force coming from the engine to move a 3,000lb vehicle from a complete stop.

The transmission also houses its own specialized brain: the Transmission Control Unit (TCU). While the engine’s computer (ECU) manages fuel and spark, the TCU manages hydraulic pressure and solenoid timing. This electronic separation ensures that gear shifts are executed smoothly. Whether it is a traditional Automatic, a driver-engaged Manual, or a reliable Continuously Variable Transmission (CVT), the goal remains the same: optimizing the engine’s output for real-world driving conditions.

How the Powertrain Operates as a Unified System

Despite being separate components, the engine and transmission must work in perfect synchronization to provide a trusted driving experience. This collaboration is facilitated by the CAN bus system, a high-speed communication network that allows the Engine Control Module (ECM) and the Transmission Control Module (TCM) to talk to each other in real-time. In modern luxury vehicles with electronic shift-by-wire systems, this communication happens hundreds of times per second.

The physical bridge between these two systems is the Flywheel (in manual cars) or the Flexplate (in automatics). This heavy metal disc is bolted to the end of the engine’s crankshaft. As the engine spins, the flywheel spins with it, providing a surface for the clutch or torque converter to grab onto. This is where the transfer of energy occurs. High-quality engineering ensures that gear shifts occur at the optimal ‘power band’ of the engine, preventing energy loss and maximizing efficiency.

The health of one component directly impacts the longevity of the other. For instance, if a transmission is “hunting” for gears—shifting up and down unnecessarily—it places localized stress on the engine’s internal components and cooling system. Conversely, an engine misfire can disrupt the smooth flow of torque, making a perfectly healthy transmission feel like it is jerking or slipping. Modern dual-clutch transmissions can shift gears in as little as 8 milliseconds, requiring millisecond-perfect timing from the engine’s ignition system to ensure the transition is seamless.

Professional Diagnosis: Distinguishing Engine Issues from Transmission Problems

Identifying whether a problem lies with the engine or the transmission is the hallmark of an expert technician. One of the most common pitfalls is assuming that a “Check Engine” light always means an engine problem. In reality, approximately 15% of all ‘Check Engine’ light occurrences are actually related to transmission performance or sensor data. Because the systems are so integrated, a fault in the transmission’s ability to shift can trigger a general warning on the dashboard.

Never confuse Engine Oil with Transmission Fluid (ATF). Engine oil is designed for high-heat lubrication and cleaning, while ATF is a specialized hydraulic fluid and friction modifier. Using the wrong fluid will destroy your clutches or bearings within miles.

So, how do you tell the difference during a drive? If your vehicle “jerks” while driving, you must determine if it’s an engine misfire or a transmission shift flare. An engine misfire usually occurs under load (acceleration) and often feels like a rhythmic “stutter” or “hiccup” accompanied by a flashing engine light. A transmission shift flare happens specifically during the transition between gears, where the RPMs spike briefly but the car doesn’t accelerate before the gear finally “slams” into place.

Engine Symptoms

Blue/White smoke, rhythmic knocking, overheating, and loss of power across all speeds.

Transmission Symptoms

Slipping between gears, grinding noises when shifting, delay when shifting into Drive, and burnt-smelling fluid.

The cost implications of these repairs also vary significantly. Engine repairs often involve quality replacement of seals, timing belts, or head gaskets, which are labor-intensive but often focus on individual components. Transmission repairs frequently involve complex hydraulic solenoids or planetary gear sets; in many modern cases, it is more professional and cost-effective to replace the entire unit rather than rebuilding the intricate internal maze of valves and clutches.

Transmission fluid should be bright red or pink and smell sweet. If it is dark brown or smells like burnt toast, your transmission is overheating and needs immediate professional attention, even if the engine is running perfectly.

In summary, while the engine and transmission are separate mechanical entities, they are functionally inseparable within the powertrain. The engine produces the raw energy through combustion, and the transmission expertly manages that energy to provide motion. Understanding this distinction is the key to reliable vehicle ownership and prevents the common pitfall of throwing money at the wrong component during a breakdown. By treating each system with its own specific maintenance schedule and using trusted, high-quality fluids, you ensure the longevity of your vehicle’s most vital organs. Ensure your vehicle stays in peak condition by scheduling a professional inspection if you notice any changes in shifting patterns or engine sound—catching a small transmission leak today can save you from a total powertrain failure tomorrow.

Frequently Asked Questions

Can a car run if the transmission is broken but the engine is good?

While the engine may start and idle perfectly, a vehicle cannot move if the transmission is non-functional. The transmission is responsible for transferring the engine’s rotational energy to the wheels. Without a working gearbox or torque converter, the engine’s power has no path to the drivetrain, rendering the car stationary despite a healthy engine.

Does a transmission rebuild include engine repair?

No, a transmission rebuild is a specialized process that focuses exclusively on the internal components of the gearbox, such as clutches, bands, and gears. Because they are separate systems, a transmission technician will not typically perform engine work unless specifically requested. These repairs involve different toolsets and expert knowledge bases within the automotive industry.

Is transmission fluid the same as engine oil?

Absolutely not. Engine oil is designed to withstand high heat and combustion byproducts while lubricating pistons. Transmission fluid (ATF) acts as a hydraulic fluid, a coolant, and a lubricant for gear friction. Using the wrong fluid can lead to catastrophic failure in either system; they have vastly different viscosities and chemical additive packages designed for their specific tasks.

Why is the transmission bolted directly to the engine?

The transmission is bolted to the engine to ensure a direct and rigid transfer of power. By mounting them together, the crankshaft can feed directly into the transmission’s input shaft with minimal energy loss. This close proximity also allows the two units to share the same chassis mounting points, reducing vibration and maintaining the alignment of the powertrain.

Do electric vehicles have both an engine and a transmission?

Electric vehicles (EVs) do not have an internal combustion engine; instead, they use an electric motor. Most EVs also utilize a simplified, single-speed transmission. While the ‘engine’ is replaced by a motor, the need for a gear reduction system (transmission) remains necessary to manage the motor’s high RPM and deliver smooth torque to the wheels efficiently.