What Happens When Your Transmission Goes Out: Mechanical Failure Basics Explained

The sudden realization that your vehicle is no longer translating engine power to the wheels is a moment of high stress for…

The sudden realization that your vehicle is no longer translating engine power to the wheels is a moment of high stress for any driver. Whether it manifests as a startling “thud” followed by a loss of momentum or a subtle, recurring slip during acceleration, the implications are the same: your drivetrain’s primary orchestrator is failing. Transmission failure is a complex mechanical event that can manifest as a subtle slip or a catastrophic, localized explosion of internal components. This comprehensive overview provides a detailed understanding of the symptoms, mechanical causes, and technical outcomes when a transmission ‘goes out,’ enabling you to make informed decisions about repairs before you find yourself stranded on the shoulder of a busy highway.

SECTION 1: Recognizing Early Warning Signs of Transmission Degradation

In the introduction to automotive maintenance, we often emphasize that the transmission is the most sensitive component in your vehicle. Unlike an engine, which might run poorly for months with a vacuum leak, a transmission operates within tight hydraulic parameters where even a slight deviation leads to failure. Recognizing the basics of degradation allows for proactive intervention.

📤 Share Image

Identifying Gear Slippage and RPM Flares

Gear slippage is the most common precursor to total failure. This occurs when the transmission attempts to shift or maintain a gear, but the internal clutch packs or bands cannot generate enough friction to hold the load. Imagine a scenario where a driver experiences a ‘flare’ in RPMs while attempting to merge onto a highway. You press the accelerator, the engine roars to 4,000 or 5,000 RPM, but the vehicle fails to accelerate proportionally. This indicates the clutch packs are no longer holding, and the transmission is effectively “slipping” between gears.

Delayed Engagement and Audible Warnings

Delayed engagement is another important red flag. This is the distinct lag—sometimes lasting two to five seconds—between shifting the selector from Park to Drive or Reverse and the actual mechanical engagement of the drivetrain. This delay often signals low hydraulic pressure or hardened internal seals. Furthermore, keep an ear out for audible indicators. Whining, clunking, or humming sounds signify mechanical friction or bearing wear. A high-pitched whine that increases with engine speed often points to a failing torque converter or a clogged internal filter starving the pump of fluid.

If you smell something “acrid” or “burnt” after a drive, pull the transmission dipstick (if your vehicle has one). Healthy fluid is bright red; dark brown or black fluid with a burnt odor indicates internal overheating and imminent failure.

By The Numbers

Failures due to overheating

Fluid oxidation threshold

SECTION 2: The Internal Mechanics of Drivetrain Failure Explained

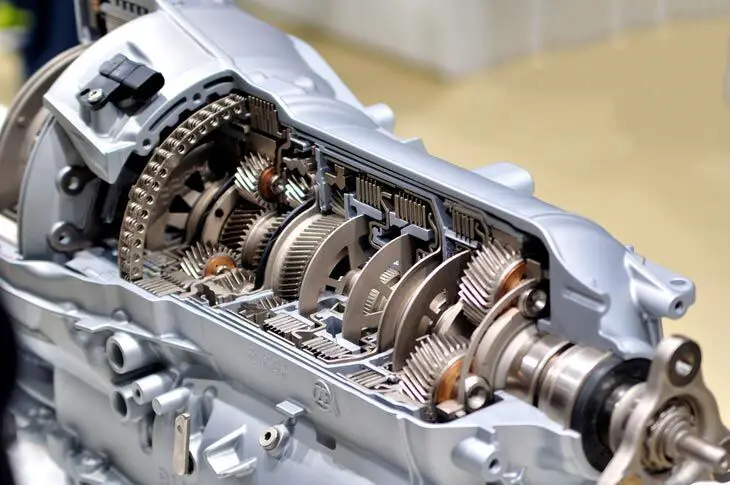

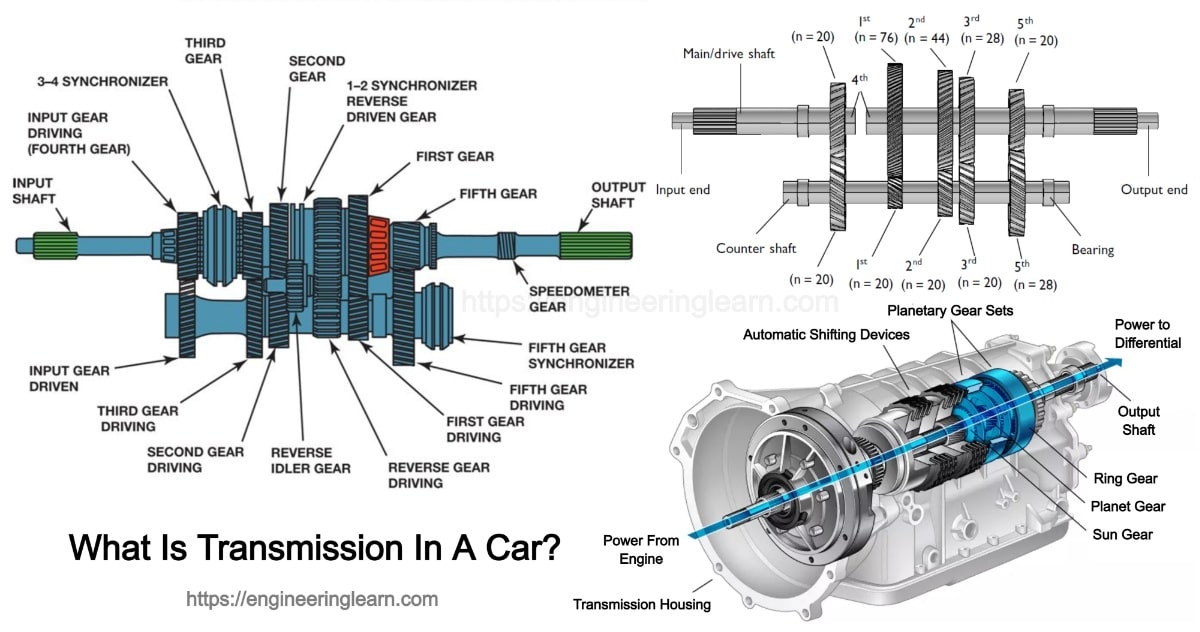

To understand what happens when a transmission fails, we must look at the fundamentals of its internal operation. Modern transmissions are marvels of hydraulic and electronic engineering, operating with tolerances as tight as 0.001 inches. At this level of precision, even microscopic metal debris can cause a total hydraulic blockage, leading to catastrophic failure.

Hydraulic Pressure and Clutch Engagement

The transmission relies on pressurized fluid to engage clutch plates and bands. If seals or gaskets deteriorate, internal pressure leaks occur. This starves the system of the very force required to hold gears in place. When pressure drops, the clutch plates rub against each other without full engagement, creating immense heat. This heat further degrades the fluid, creating a “death spiral” of mechanical wear.

The Role of Solenoids and Planetary Gear Sets

In automatic transmissions, failed solenoids—electro-magnetic valves—are often the culprit for specific gear losses. Consider a technical breakdown: a single failed shift solenoid in a modern 6-speed transmission can prevent the unit from shifting past second gear. While the gears themselves may be intact, the “brain” (the valve body) cannot direct the fluid to the next gear set. However, if the failure is physical, metal shavings and debris from worn synchronizers or needle bearings circulate through the fluid. These fragments act like liquid sandpaper, destroying the planetary gear sets and the torque converter’s stator.

Once metal debris enters the transmission fluid, it often gets lodged in the torque converter and cooler lines. A simple “rebuild” of the gearbox without replacing the converter or flushing the lines will lead to a second failure within weeks.

SECTION 3: Total Failure Scenarios: What Happens During Operation

When a transmission finally “goes out” while you are driving, the experience can range from a nuisance to a serious safety hazard. The key points to remember involve how your vehicle’s computer—the Transmission Control Module (TCM)—handles the crisis.

Limp Home Mode (Limp Mode)

Modern vehicles are equipped with a software-driven failsafe known as ‘Limp Mode.’ This is typically triggered by input/output speed sensor discrepancies exceeding 10%. In a typical case study, a vehicle entering Limp Mode on a busy thoroughfare will restrict the speed to 30 MPH and lock the gear in 2nd or 3rd. This prevents the transmission from hunting for gears and causing further internal carnage, but it also means you lose the ability to accelerate quickly or reach highway speeds.

Complete Loss of Propulsion

The most alarming scenario is the complete loss of torque transfer. You may be driving uphill or carrying a heavy load when a drive band snaps. The engine will rev freely as if it is in neutral, but the wheels receive zero power. In rare, severe cases, the drivetrain can “seize” or lock up, causing the drive wheels to skid or hop as the internal gears jam against each other. This is a catastrophic failure that requires immediate, controlled navigation to the shoulder.

📋

Safety Protocol: When the Transmission Fails

Do not panic if the engine revs. Keep your hands on the wheel and focus on steering; your power steering will still function as long as the engine is running.

Activate your hazard lights immediately. Use the vehicle’s remaining momentum to coast toward the right-hand shoulder or a safe parking area.

Once stopped, shift to Park and engage the emergency brake. Do not attempt to “restart” the car to fix the issue; this can worsen internal damage.

SECTION 4: Diagnostic Procedures and Professional Assessment Basics

Before you authorize a multi-thousand dollar replacement, you must ensure the diagnosis is accurate. A professional technician follows a specific set of fundamentals to determine if the unit is truly “gone” or if the issue is peripheral.

Electronic Scanning and the Pan Drop

The process begins by pulling Diagnostic Trouble Codes (DTCs) using an OBD-II scanner. Codes in the P0700 to P0800 range are transmission-specific. However, a code for a “gear ratio error” doesn’t tell you why it failed—only that it did. The most definitive test is the ‘Pan Drop’ inspection. A technician finding large chunks of friction material or ‘silver glitter’ (fine metal shavings) in the transmission pan confirms that a simple fluid flush or solenoid replacement will not fix the issue. This indicates physical hardware destruction.

Fluid Analysis and the “Milkshake” Test

Technicians also check for coolant contamination. If the internal barrier in the radiator fails, engine coolant can mix with transmission fluid. This creates a “strawberry milkshake” appearance. Since coolant dissolves the adhesives holding the clutch friction material together, this scenario almost always necessitates a total rebuild or replacement.

Stall Test

Evaluates the holding power of the torque converter and clutches under load while the vehicle is stationary.

Pressure Test

Attaching a gauge to the transmission’s pressure ports to verify if the oil pump is meeting factory specifications.

SECTION 5: Recovery and Resolution: Repair, Rebuild, or Replace Overview

Once the diagnosis is final, you face a decision matrix based on cost, vehicle longevity, and warranty requirements. The average cost of a transmission replacement in the United States currently ranges between $2,500 and $5,500, but your specific path depends on the type of failure.

The Three Paths to Resolution

A “Soft Parts” rebuild is viable if the main gear train (the hard parts) is still intact. This involves replacing clutches, seals, and gaskets. However, if the planetary gears are damaged, a remanufactured unit is often the superior choice. Comparing a $3,500 remanufactured unit with a 3-year/unlimited mile warranty against a $1,200 used unit with a 30-day ‘start up’ warranty reveals the risk: used transmissions from salvage yards are unknowns that may fail shortly after the labor-intensive installation.

✅ Pros of Reman Units

- Factory-corrected design flaws

- New torque converter included

- Nationwide warranty coverage

- Updated internal electronics

❌ Cons of Used Units

- Unknown maintenance history

- Labor cost is paid twice if it fails

- No core value refund

- High risk of “shelf” seal rot

The Decision Matrix

When the cost of repair exceeds 50-60% of the total book value of the vehicle, many owners choose to trade the vehicle in or sell it as-is. However, in the current automotive market where new car prices are elevated, spending $4,000 to keep a reliable $10,000 vehicle on the road for another five years is often the most fiscally responsible important step.

Summary Points: Total transmission failure is usually preceded by warning signs like slipping, strange noises, or burnt fluid. Internal failure involves a loss of hydraulic pressure or physical destruction of gear sets and clutch packs. Resolution options range from targeted sensor replacement to full remanufactured unit installation, each with distinct financial implications.

Call to Action: If you suspect your transmission is beginning to fail, consult a certified technician immediately to perform a diagnostic scan and fluid analysis before a total breakdown occurs. Catching a leak or a failing sensor today can prevent a total mechanical failure tomorrow.

Frequently Asked Questions

Can I drive my car at all if the transmission is going out?

It is highly discouraged to drive a vehicle with a failing transmission. Doing so can cause additional damage to the engine or drivetrain and poses a significant safety risk if the vehicle loses power in traffic. Even a minor slip can quickly escalate into a total mechanical lock-up, potentially causing an accident or leaving you stranded in a dangerous location.

How do I know if the problem is the transmission or just a sensor?

A professional diagnostic scan is essential to differentiate between the two. If the vehicle shifts erratically but the fluid is clean and there are no metallic noises, it may be a failed shift solenoid or speed sensor. However, if the fluid smells burnt or contains metal shavings, the issue is mechanical and likely requires a rebuild or replacement regardless of sensor health.

How long does it typically take to fix a failed transmission?

A standard transmission replacement usually takes between 8 to 15 hours of labor, which translates to 2 to 4 business days in a shop environment. If you choose a custom rebuild of your existing unit, the process may take a week or longer as the technician must disassemble the unit, order specific hard parts, and meticulously reassemble the internal gear train.

Does a check engine light always mean the transmission is failing?

Not necessarily, but many transmission issues trigger a check engine light through the Transmission Control Module (TCM). Specific codes, such as P0700, indicate the TCM has detected a fault. While the light could represent a minor electrical glitch, it often serves as the first warning that the transmission is operating outside of its designated hydraulic pressure or temperature parameters.

Is it worth replacing a transmission on an older high-mileage vehicle?

This depends on the vehicle’s overall condition and market value. If the cost of the transmission replacement exceeds 60-70% of the car’s ‘Blue Book’ value, it is often considered a total loss. However, if the rest of the vehicle (engine, suspension, body) is in excellent condition, a remanufactured transmission can extend the vehicle’s lifespan for several more years.