When To Check Transmission Fluid: Essential Intervals And Warning Signs Explained

The automatic transmission is arguably the most complex mechanical component in your vehicle, relying on a precise balance of hydraulic pressure, cooling,…

The automatic transmission is arguably the most complex mechanical component in your vehicle, relying on a precise balance of hydraulic pressure, cooling, and lubrication to function. While most drivers diligently track their engine oil levels, many neglect their transmission fluid until a major mechanical failure occurs, often resulting in repair bills exceeding several thousand dollars. Understanding when and how to inspect this critical lubricant is the single most effective way to extend the lifespan of your drivetrain. This article provides a professional overview of when to check transmission fluid, including industry-standard maintenance schedules, critical sensory warning signs, and the fundamentals of the inspection process to ensure your vehicle remains roadworthy for years to come.

Understanding Transmission Fluid Roles and Functionality

📤 Share Image

To appreciate the necessity of regular inspections, one must first master the basics of what Automatic Transmission Fluid (ATF) actually does. Unlike engine oil, which primarily serves as a lubricant, ATF is a multi-functional medium. In an automatic transmission, the fluid acts as a hydraulic lubricant, a coolant, and the very power-transfer medium that allows the vehicle to move. Within the torque converter, the fluid transmits power from the engine to the transmission through hydrodynamic energy—if the fluid level is low or the quality is compromised, the vehicle simply cannot move efficiently.

Modern ATF, such as Dexron VI or Mercon V, contains a sophisticated package of friction modifiers. These chemicals are important because they ensure that the internal clutch packs engage smoothly without “shuddering.” Furthermore, the fluid facilitates heat dissipation. Transmissions are internal combustion’s hottest neighbors, operating optimally between 175 and 200 degrees Fahrenheit. The fluid carries heat away from moving parts to the transmission cooler, preventing the hardening and cracking of internal seals and gaskets. If this cooling cycle fails, the gaskets become brittle, leading to internal pressure losses and eventual gear slippage.

Thermal Degradation Statistics

Ideal Operating Temp

Lifespan reduction per 20°F increase

It is vital to distinguish between fluid types. Traditional ATF is designed for planetary gearsets, whereas Continuously Variable Transmissions (CVT) require specialized fluids that maintain high friction for metal belts. Similarly, Dual-Clutch Transmissions (DCT) utilize lubricants that behave more like a hybrid between gear oil and ATF. Think of the fluid as the blood in a human body; if the pressure drops or the chemistry degrades, the entire system faces imminent failure.

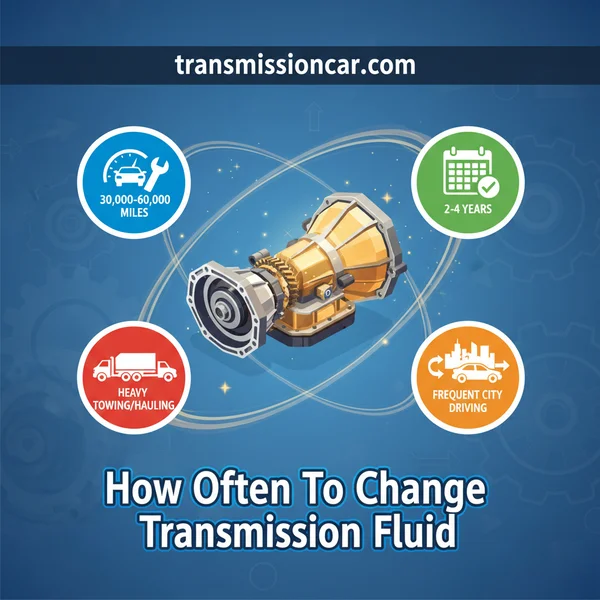

Recommended Maintenance Intervals for Checking Transmission Fluid

A professional maintenance overview dictates that there are two types of intervals: the “Quick Check” and the “Service Interval.” Industry experts recommend the Once a Month rule for visual inspections. This frequency is standard for catching slow leaks—often from a pan gasket or an axle seal—before they result in a low-pressure condition that burns out clutch plates. Because transmissions are closed systems, any drop in fluid level on the dipstick indicates a leak that requires immediate professional attention.

The “Service Interval,” typically occurring every 30,000 to 60,000 miles, is when the key points of maintenance shift from a simple check to a fluid exchange or flush. According to the Car Care Council, low fluid levels are the primary cause of 90% of all automatic transmission failures. While many modern manufacturers claim their vehicles use “Lifetime” fluid, this is often a marketing term referring to the duration of the powertrain warranty, not the actual mechanical life of the car. For long-term reliability, even “sealed” transmissions (those without a dipstick) should be inspected by a technician at least once a year.

If you frequently tow a trailer, drive in mountainous terrain, or spend hours idling in heavy traffic, you fall under the “Severe Driving” category. In these cases, heat builds up rapidly, and you should check your fluid levels every 1,000 miles during heavy use seasons to ensure no thermal breakdown has occurred.

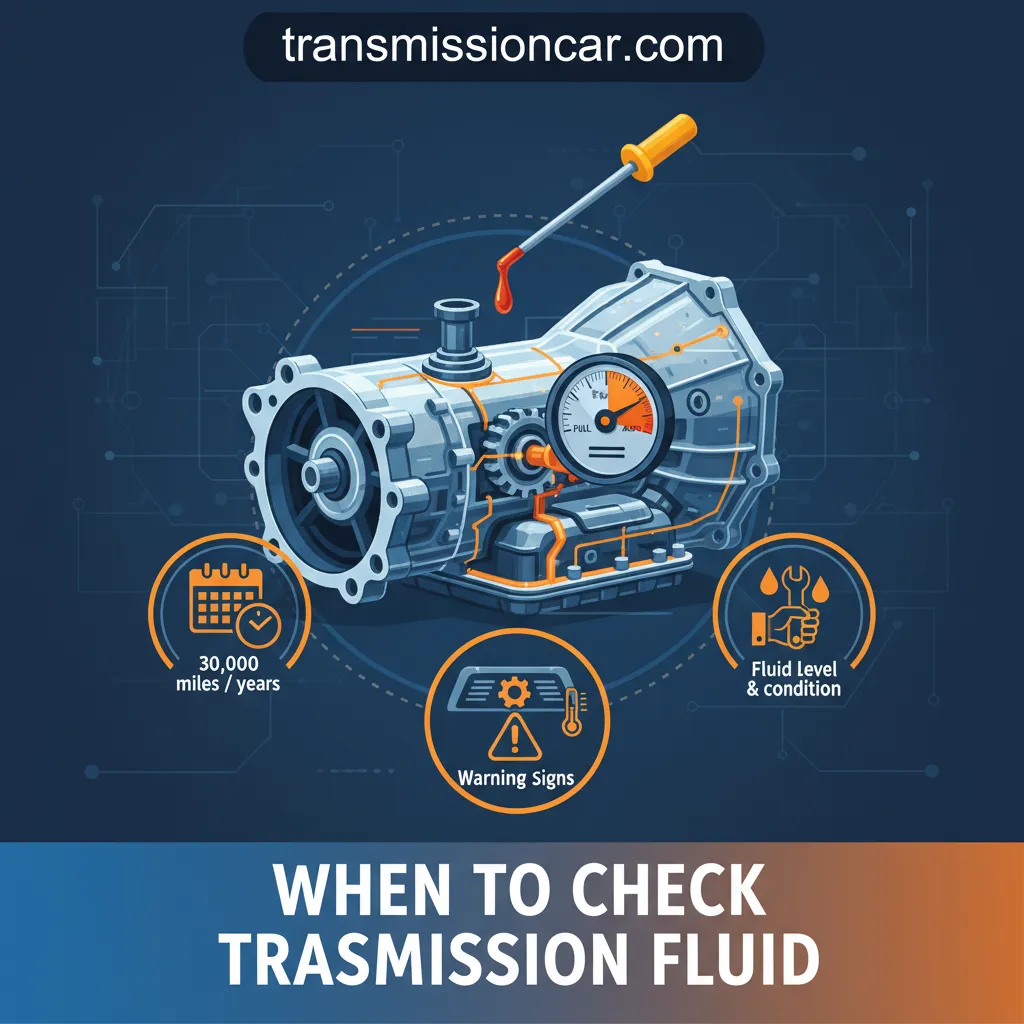

Physical Warning Signs That Indicate Immediate Inspection

Waiting for a scheduled interval is a mistake if your vehicle is providing sensory feedback that something is wrong. One of the most common fundamentals of transmission diagnostics is identifying delayed engagement. This is the noticeable hesitation—often lasting one to three seconds—when you shift the selector from Park into Drive or Reverse. This delay is usually caused by low hydraulic pressure; the pump cannot move enough fluid to engage the clutch packs instantly.

Auditory cues are equally revealing. A high-pitched whining noise that increases in frequency with engine RPM often signifies that air is entering the transmission pump because the fluid level is too low to maintain a consistent prime. If you hear grinding or clunking during a shift, the fluid has likely lost its lubricating properties, allowing metal-on-metal contact.

The Visual and Olfactory Analysis

When you pull the dipstick, you are performing a critical introduction to the state of your transmission’s health. You must evaluate three factors: color, smell, and clarity.

- Healthy ATF: Bright, translucent red. It should have a slightly sweet or “oily” chemical smell.

- Oxidized Fluid: Dark “chocolate” brown. This indicates the fluid has reached its thermal limit. At this stage, it has lost roughly 70% of its protective additives.

- Burnt Fluid: Opaque black with a “burnt toast” smell. This is a warning sign of internal mechanical damage, such as burnt clutch linings.

“Transmission Slip” occurs when the engine revs during a gear change without a corresponding increase in vehicle speed. This is a critical safety issue. If your Check Engine Light (CEL) illuminates with an OBD-II code like P0700 (Transmission Control System Malfunction), check your fluid immediately before driving further.

How Driving Habits and Environment Dictate Inspection Frequency

Your geographic location and daily commute play a massive role in fluid degradation. Ambient temperatures are a primary driver of fluid stress. In sub-zero winters, the fluid becomes highly viscous (thick), struggling to flow through small valve body orifices until the vehicle warms up. Conversely, triple-digit summers prevent the transmission cooler from shedding heat effectively. Important to note: Stop-and-go urban driving can increase transmission temperatures by up to 30% compared to steady highway speeds, as the torque converter is constantly working to manage the vehicle’s inertia.

High-Torque Loads

Towing a 5,000lb trailer doubles the heat output. Inspect fluid bi-weekly during towing seasons.

Contaminant Entry

Dusty or sandy environments allow microscopic particles to bypass seals, turning fluid into an abrasive paste.

Off-roading and driving on steep inclines introduce a physical challenge: fluid sloshing. When a vehicle is at an extreme angle, the fluid in the pan shifts away from the pump pickup. This can lead to momentary starvation and aeration. If you frequently traverse steep grades, checking for a “full” level (the top of the hot range) is essential to ensure the pump never sucks in air, which causes foaming and erratic shifting.

Basics of the Inspection Process: A Step-by-Step Overview

Performing the check incorrectly is almost as dangerous as not checking it at all, as it leads to inaccurate readings. Most automatic transmissions are designed to be checked while the engine is running and the fluid is at operating temperature. This is because the torque converter and the cooling lines must be full of fluid to get an accurate reading of the remaining oil in the pan.

📋

Professional Inspection Guide

Park the vehicle on a level surface. Keep the engine running until it reaches operating temperature (usually after 10-15 minutes of driving).

With your foot on the brake, move the gear selector slowly through every position (P-R-N-D-L) and back to Park. This ensures fluid is distributed through all valve bodies.

Pull the dipstick, wipe it with a lint-free cloth, re-insert it fully, and pull it again. Check the level against the “HOT” markings. Never use the “COLD” mark unless the engine has just started.

A critical nuance involves manufacturer-specific procedures. For example, most Honda and Acura vehicles require the fluid to be checked with the engine off shortly after it has reached operating temperature, whereas General Motors and Ford almost universally require the engine to be running. Consulting your Owner’s Manual is the only way to verify the correct procedure for your specific vehicle.

✅ The Blotter Test

- Drip fluid onto a white paper towel.

- Wait 30 seconds for the fluid to spread.

- If a dark center remains, internal particles are present.

- If it spreads as a clear red circle, the additives are still active.

❌ Overfilling Risks

- Causes fluid to “foam” as gears hit the surface.

- Aerated fluid cannot hold hydraulic pressure.

- Leads to erratic shifting and overheating.

- Can blow out seals due to excessive pressure.

If your vehicle is a “sealed unit,” the basics change. You will likely find no dipstick under the hood. In these cases, the check must be performed from under the vehicle via an overflow plug while the transmission is at a specific temperature (monitored via a scan tool). For most owners, this necessitates a trip to a professional service center every 30,000 miles to ensure the level remains within spec.

Summary and Final Recommendations

Maintaining your transmission is not a matter of guesswork; it is a disciplined practice of observation and routine. As we have explained, routine monthly checks are your best defense against catastrophic failure. By paying close attention to sensory symptoms like burnt smells, slipping gears, and darkening fluid color, you can intervene before a minor leak becomes a major mechanical disaster. Remember that external factors—towing, urban traffic, and extreme weather—dictate a more aggressive inspection schedule. Do not rely solely on “Lifetime” fluid claims. Consult your vehicle’s service manual today to identify your specific dipstick location and protocol. Scheduling your next fluid inspection now is a small investment that ensures the long-term reliability and performance of your vehicle’s drivetrain.

Frequently Asked Questions

Can I check my transmission fluid while the engine is cold?

While most dipsticks have a ‘cold’ mark, it is primarily used for a preliminary check after a fluid change. For an accurate reading, the fluid should be at operating temperature (usually after 15 minutes of driving). Cold fluid is denser and will show a lower level on the dipstick than is actually present when the vehicle is in use.

How do I check transmission fluid in a car without a dipstick?

Vehicles with ‘sealed’ transmissions require a more technical approach. You generally need to raise the vehicle on a level lift, bring the transmission to a specific temperature monitored via an OBD-II scanner, and then remove a ‘check plug’ or ‘overflow plug’ from the bottom or side of the transmission case. If fluid drips out, the level is correct.

What does it mean if my transmission fluid is light brown?

Light brown fluid indicates the beginning of oxidation and the depletion of vital additives. While not an immediate emergency like black, burnt-smelling fluid, it is a clear signal that a fluid exchange should be scheduled soon. It suggests the fluid is losing its ability to properly lubricate and cool the internal components of the transmission.

Is it better to check transmission fluid in Park or Neutral?

This depends entirely on the vehicle manufacturer. Most General Motors and Ford vehicles require the car to be in Park, while many Chrysler and some Mitsubishi products require the transmission to be in Neutral with the parking brake engaged. Always refer to the instructions printed on the dipstick itself or the owner’s manual to ensure an accurate reading.

How often should I check the fluid if I tow a trailer regularly?

If you are frequently towing or hauling heavy loads, your transmission fluid is subject to extreme thermal stress. In these cases, it is recommended to check the fluid level and condition every two weeks or every 1,000 miles. This frequency ensures that any fluid thinning or oxidation caused by high temperatures is caught before it damages the clutches.