Why Check Transmission Fluid While the Engine Is Running?

📌 Quick Summary Checking transmission fluid while the engine is running is essential because the internal pump must be active to circulate…

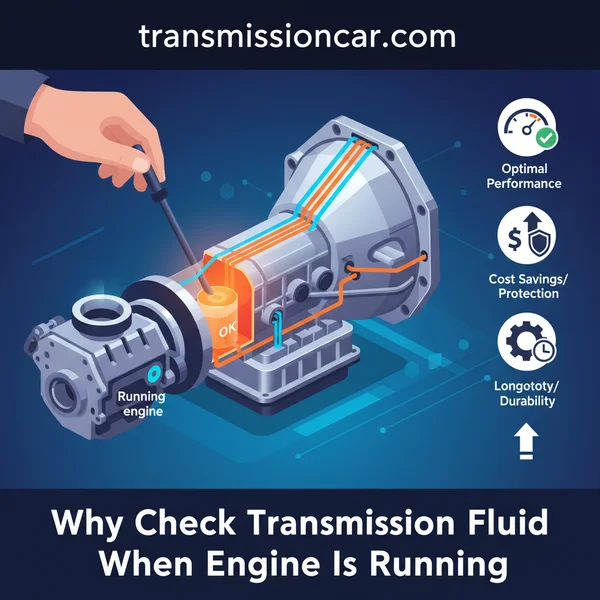

Checking transmission fluid while the engine is running is essential because the internal pump must be active to circulate fluid through the torque converter and cooling lines. If the engine is off, fluid settles in the pan, creating a false high reading that can lead to a dangerously underfilled system.

🎯 Key Takeaways

- The transmission pump must be active to measure the true operational fluid level.

- Engine-off readings are inaccurate due to fluid draining back into the pan.

- Accurate measurements require the fluid to reach full operating temperature for expansion.

- Checking while running prevents the risk of underfilling and subsequent gear damage.

- Always verify if your specific vehicle requires Park or Neutral for the check.

Checking your transmission fluid while the engine is running isn’t just a suggestion; it is a mechanical necessity for an accurate reading. Unlike engine oil, which rests in a reservoir when the vehicle is off, automatic transmission fluid (ATF) is a hydraulic fluid that must be actively circulating to be measured correctly. If you check the dipstick with the engine off, you are only seeing how much fluid has pooled in the bottom of the pan, not how much is available to operate the vehicle.

This distinction matters because an overfilled or underfilled transmission can lead to catastrophic failure. An accurate reading ensures that the hydraulic pressure is sufficient to engage clutches and lubricate moving parts under load. By checking the level while the pump is active, you are measuring the “working volume” of the system. This gives you a real-time snapshot of the fluid levels exactly as they exist while you are driving down the road.

The Role of the Transmission Pump and Torque Converter

The primary reason the engine must be running is to engage the transmission’s internal oil pump. In an automatic transmission, the pump is typically driven by the torque converter hub, which is bolted directly to the engine’s flexplate. As long as the crankshaft is turning, the pump is spinning. This pump is the heart of the system, responsible for pulling fluid out of the pan and pushing it through the entire transmission architecture.

Filling the Hydraulic Circuits

When the engine is running, the pump forces fluid into several critical areas that remain empty or partially empty when the vehicle is off. These include:

- The Torque Converter: This large, donut-shaped component acts as a fluid coupling between the engine and the transmission. It holds a significant volume of fluid (often several quarts) that must be fully “charged” or pressurized to show an accurate level on the dipstick.

- The Valve Body: This is the brain of the transmission. It contains a complex maze of channels and valves that require constant hydraulic pressure to remain primed.

- Cooler Lines and Heat Exchangers: Fluid is constantly pumped out of the transmission to an external cooler and back again. This circuit must be active to ensure the fluid volume within the lines is accounted for.

Maintaining Constant Pressure

An automatic transmission relies on line pressure to function. When you pull the dipstick while the engine is idling, you are seeing the level of the fluid reservoir while the system is under pressure. If the pump is off, that pressure vanishes, and the fluid that should be in the torque converter and valve body begins to evacuate, leading to a misleadingly high level on the dipstick. To get a true measurement, the pump must be moving fluid through every orifice and gallery in the unit.

Everything You Need to Know About Checking Transmission Fluid While Running

Checking your transmission fluid is a vital part of vehicle maintenance, but many car owners are surprised to learn that, unlike engine oil, transmission fluid must almost always be checked while the engine is idling. This guide covers the specific steps required to get an accurate reading and explains the mechanical reasons why the engine must be running to ensure your transmission is properly lubricated. Following these steps correctly prevents the common mistake of overfilling or underfilling your transmission, both of which can lead to catastrophic mechanical failure and expensive repair bills.

Step 1: Achieve Optimal Operating Temperature

What you need: Your vehicle, a clear road, and approximately 15 to 20 minutes of driving time.

Instructions: Transmission fluid is a hydraulic fluid that expands significantly as it heats up. To get an accurate reading on the dipstick, the fluid must be at “operating temperature,” which is typically between 160 and 175 degrees Fahrenheit. Simply idling the car in the driveway isn’t enough to warm the transmission; you need to drive the vehicle for at least 10 to 15 miles. This ensures the fluid has circulated through the torque converter, the internal clutches, and the cooling lines. If you check the fluid when it is cold, the level will appear much lower than it actually is, potentially leading you to add too much fluid and causing aeration or foaming during operation.

Pro Tip: Avoid checking the fluid immediately after heavy towing or high-speed mountain driving, as the fluid may be “heat-soaked” and temporarily expanded beyond the normal “Hot” markers.

Step 2: Position the Vehicle on a Level Surface

What you need: A flat, paved surface such as a garage floor or a level driveway.

Instructions: Gravity is your enemy when it comes to getting an accurate reading on a dipstick. If the vehicle is parked on an incline or a decline, the fluid in the transmission pan will tilt toward one side. Since the dipstick tube enters the pan at a specific point, an uneven vehicle will result in a reading that is either falsely high or falsely low. Ensure the vehicle is in a stable, flat area. This is also a safety requirement; because the engine will be running during the check, you need to ensure the vehicle cannot roll or move while you are under the hood working near moving parts.

Pro Tip: If you aren’t sure if your driveway is level, use a carpenter’s level on the door sill or look at how water pools on the ground nearby.

Step 3: Cycle Through the Gear Range

What you need: A running engine, the foot brake firmly applied, and the gear selector.

Instructions: With the engine idling and your foot firmly on the brake pedal, slowly move the gear shifter through every position (Park, Reverse, Neutral, Drive, and any low gear ranges). Hold the shifter in each gear for about 5 to 10 seconds before moving to the next. This process is crucial because it opens the various hydraulic valves within the transmission’s valve body, allowing the fluid to fill every passage, clutch pack, and the torque converter. This “primes” the system so that the fluid level remaining in the pan—where the dipstick measures—is the true reservoir level available for the pump during operation.

Pro Tip: Listen for any unusual clunking or delayed engagements during this process; this is a great time to do a “silent” diagnostic check on your transmission’s health.

Step 4: Maintain Engine Idle (The “Why” Step)

What you need: The vehicle’s parking brake engaged and the engine left running in Park (or Neutral, depending on the manufacturer’s manual).

Instructions: This is the most critical step. Unlike engine oil, which drains into a sump when the car is off, transmission fluid is constantly being moved by an internal pump. When the engine is running, the transmission pump draws fluid from the pan and sends it through the torque converter and cooling circuits. If you turn the engine off, the fluid in those components drains back into the pan, making the fluid level appear much higher than it actually is. By keeping the engine running, you are measuring the “working level” of the fluid—the actual amount of fluid available while the car is in motion. This prevents the system from running dry during gear shifts.

Pro Tip: Always double-check your owner’s manual; while 95% of cars require the engine to be running in “Park,” some specific Honda and Acura models require the check to be done within 60 seconds of turning the engine OFF.

Step 5: Safety Prep and Locating the Dipstick

What you need: Work gloves, safety glasses, and a clean, lint-free microfiber cloth or paper towel.

Instructions: Open the hood and secure it with the prop rod. Because the engine is running, you must be extremely cautious of the cooling fans, which can turn on automatically at any time, and the serpentine belt, which is spinning at high speeds. Locate the transmission dipstick, which is usually colored bright red or yellow and is located further back toward the firewall compared to the engine oil dipstick (which is usually closer to the front). Ensure your clothing and hair are tucked away. The heat from the radiator and engine block will be intense, so the use of gloves is highly recommended to prevent burns when reaching for the handle.

Pro Tip: Never use a fuzzy rag or a dirty towel to wipe the dipstick. Even a tiny piece of lint or a grain of sand entering the transmission can clog a valve and cause shifting issues.

Step 6: The Initial Pull and Cleaning

What you need: Your lint-free cloth and the dipstick.

Instructions: Pull the dipstick out of the tube carefully. You will likely see fluid splashed all the way up the metal blade; this is normal because the fluid is circulating and splashing while the engine runs. This first reading is completely inaccurate and should be ignored. Take your lint-free cloth and wipe the dipstick entirely clean, from the handle down to the very tip. Pay close attention to the “Hot” and “Cold” or “Add” and “Full” markings at the bottom. Once the blade is dry and clean, you are ready for the actual measurement. This ensures that the “line” you see on the next pull is the actual surface level of the fluid.

Pro Tip: If the dipstick feels “stuck,” give it a slight twist to break the vacuum seal of the O-ring before pulling.

Step 7: The Final Measurement and Analysis

What you need: A steady hand and good lighting.

Instructions: Reinsert the dipstick fully into the tube, making sure it seats all the way down. Wait two seconds, then pull it out again. Hold the dipstick level (don’t point the tip up, or the fluid will run toward the handle and ruin the reading). Look at where the fluid ends on the blade. Since you warmed the car up in Step 1, the level should be within the “HOT” crosshatch or between the two upper holes. If it is below the “HOT” line, you need to add fluid. Additionally, look at the color: it should be translucent pink or bright red. If it is dark brown, black, or smells like burnt toast, your fluid has oxidized and needs to be changed immediately.

Pro Tip: Check both sides of the dipstick. If one side is higher than the other, always trust the lower reading, as the higher side may have picked up residual fluid from the walls of the tube.

✅ Final Checklist

- Was the car driven for at least 15 minutes to reach operating temperature?

- Is the vehicle currently idling on a flat, level surface?

- Did you cycle through all gears (P, R, N, D) before checking?

- Is the fluid level between the “HOT” markers on the dipstick?

- Is the fluid bright red/pink and free of any burnt odor or debris?

Important Notes:

- Safety Warning: Keep all loose clothing, jewelry, and fingers away from the spinning radiator fan and drive belts while the engine is running.

- When to Seek Help: If you see silver metallic flakes in the fluid or if the fluid is milky (indicating coolant contamination), stop driving and consult a mechanic immediately.

- Estimated Time: 20-30 minutes (including drive time).

- Cost Range: $0 (for a check) to $15-$40 (if you need to add 1-2 quarts of specialized ATF).

Understanding Fluid Drain Back and False Pan Readings

The concept of “drain back” is the mechanical phenomenon that occurs the moment you turn off your ignition. In a static state, gravity becomes the dominant force in your transmission. Without the pump actively pulling fluid upward and into the various clutches and drums, the fluid that was once suspended in the upper sections of the transmission begins to leak back down into the oil pan.

The “False High” Phenomenon

If you check your transmission fluid while the engine is off, you will almost always see a reading that is significantly above the “Full” or “Hot” mark. This is a “false high.” Because the torque converter and the cooling lines have drained their contents back into the sump, the pan is temporarily overfilled with fluid that doesn’t belong there during normal operation. If you were to remove fluid based on this stagnant reading, you would leave the transmission dangerously low once you started the engine and the pump began redistributing that fluid.

Why Gravity Is an Unreliable Mechanic

The rate of drain back isn’t consistent across all vehicles. Some transmissions have check valves designed to keep fluid in the torque converter, but these valves are rarely 100% airtight. Factors that influence drain back include:

- Ambient Temperature: Thinner, hot fluid drains back into the pan much faster than cold, viscous fluid.

- Valve Wear: In older transmissions, worn internal seals allow fluid to retreat into the pan more quickly.

- System Design: Some heavy-duty transmissions have larger cooling circuits that hold more fluid, leading to more dramatic fluctuations between “running” and “off” readings.

By keeping the engine running in Park or Neutral (depending on the manufacturer’s spec), you stabilize the fluid level. You ensure that the “drain back” effect is neutralized because the pump is constantly fighting gravity, keeping the fluid exactly where it needs to be for the transmission to shift gears safely.

Thermal Expansion: Why Operating Temperature is Critical

Transmission fluid is a highly specialized hydraulic oil that is incredibly sensitive to temperature changes. Unlike engine oil, which stays relatively consistent in volume, Automatic Transmission Fluid (ATF) undergoes significant thermal expansion. If you check the level when the fluid is cold, you are only seeing a fraction of the “working” volume, which can lead to significant measurement errors.

The “Cold” vs. “Hot” Marks on the Dipstick

Most transmission dipsticks feature two distinct sets of markings: one for “Cold” and one for “Hot.” It is a common misconception that the “Cold” mark is the final goal. In reality, the “Cold” range is merely a reference point to ensure there is enough fluid to safely start the engine and drive until it reaches operating temperature. The only truly accurate reading is the one taken when the fluid is hot.

- Volume Increase: As ATF reaches its operating temperature (usually between 175°F and 200°F), its molecules move more rapidly and take up more physical space.

- The 15-Minute Rule: It typically takes about 15 to 20 minutes of active driving for the fluid to fully expand. Idling in the driveway often isn’t enough to reach this state.

Avoiding the Pitfalls of Overfilling

If you check your fluid when the engine is cold and off, the level will appear deceptively low because the fluid hasn’t expanded and has settled into the pan. If you “top it off” to the full line under these conditions, you will likely overfill the system. Overfilling is just as dangerous as underfilling; it causes the rotating internal components to churn air into the fluid. This “aerated” fluid becomes foamy, losing its ability to lubricate parts or provide the hydraulic pressure needed for gear shifts.

Hydraulic Differences Between Park and Neutral Positions

While having the engine running is the general rule, the specific gear position can drastically change your reading. This is due to how the internal hydraulic pump routes fluid through the valve body and the torque converter. Depending on the design of your transmission, the fluid level might fluctuate depending on whether the shifter is in “Park” or “Neutral.”

Fluid Flow and Valve Body Engagement

In many classic transmission designs—particularly those found in older Chrysler, Dodge, and Jeep vehicles—the fluid does not circulate through the cooling lines or the torque converter while the vehicle is in “Park.” In these specific systems, checking the fluid in “Park” will result in an incorrectly high reading because the fluid has drained back into the sump rather than being distributed through the system.

- Pump Circulation: Placing the vehicle in “Neutral” (with the parking brake firmly engaged) ensures that the pump is actively pushing fluid through the entire cooling circuit.

- Filling the Torque Converter: Running the engine ensures the torque converter is completely filled with fluid, which is essential for an accurate measurement of the remaining volume in the pan.

Manufacturer Specifics: Check Your Owner’s Manual

Not every car follows the same protocol. For instance, most Hondas require the engine to be turned off, but the check must be performed within 60 to 90 seconds of shutting down a warm engine. Conversely, many modern “sealed” transmissions don’t even have a dipstick, requiring a professional plug-check at specific temperatures. Always consult your owner’s manual to confirm if your vehicle requires a “Park” or “Neutral” reading to avoid a false positive that could lead to transmission slip.

Conclusion

Understanding why you check transmission fluid while the engine is running is the key to maintaining a healthy vehicle. By ensuring the pump is active and the fluid has reached its full thermal expansion, you get a “live” look at the hydraulic pressure that keeps your gears turning. This simple habit prevents the twin dangers of aeration from overfilling and friction damage from underfilling.

As a next step, take your vehicle for a brief drive to reach operating temperature, find a level surface, and check your fluid according to your manual’s gear recommendation. If you notice the fluid is dark or smells burnt, schedule a professional inspection immediately. Staying proactive today ensures your transmission remains smooth and reliable for the road ahead!

💬 Quick Questions & Answers

Why does the engine need to be on to check transmission fluid?

The engine must be running so the transmission pump can fill the torque converter and lines, showing the actual level available for gear operation.

What is ‘drain back’ in a transmission?

Drain back occurs when the engine is off and fluid flows out of the upper components back into the pan, causing an artificially high reading.

Can I check the fluid when the engine is cold?

You can, but it will be inaccurate; the fluid must be hot to reach the ‘Hot’ mark due to thermal expansion.

What happens if I check the fluid while the engine is off?

You will likely see a full dipstick even if the system is low, leading you to under-fill the transmission.

Should the car be in Park or Neutral?

Most vehicles should be in Park, but some manufacturers require Neutral to ensure the pump is fully engaged.

❓ Frequently Asked Questions

Why is the transmission pump vital for an accurate reading?

The pump is responsible for drawing fluid from the pan and pressurized it through the entire system. Without the pump running, the fluid sits idle in the pan, which does not represent the volume required for the vehicle to actually shift and drive.

How does fluid drain back lead to transmission damage?

When the engine stops, gravity pulls fluid from the cooling lines and torque converter into the oil pan. If you check it then, the dipstick looks full; however, once you start the car, that fluid is sucked back into the system, leaving the pan empty and the gears unlubricated.

Why is temperature so important when checking transmission fluid?

Transmission fluid has a high coefficient of thermal expansion, meaning it grows significantly in volume as it heats up. Checking it cold will result in a reading below the operational line, even if the system has the correct amount of fluid.

Are there any exceptions to checking fluid while running?

Yes, certain manufacturers, most notably Honda and Acura, often specify that the fluid should be checked shortly after the engine has been turned off. Always consult your owner’s manual for your vehicle’s specific requirements.

What are the symptoms of low transmission fluid if I misread the dipstick?

If you under-fill because of a false high reading, you may experience slipping gears, delayed engagement, erratic shifting, or a whining noise from the transmission pump as it sucks in air.

Does the vehicle need to be on a level surface?

Absolutely; checking the fluid on an incline will cause the fluid to pool at one end of the pan, giving a completely inaccurate reading on the dipstick regardless of whether the engine is running.