Why Is My Transmission Slipping: Technical Causes And Diagnostic Overview

When you press the accelerator, you expect a direct and immediate response from your vehicle; however, a spiking tachometer paired with a…

When you press the accelerator, you expect a direct and immediate response from your vehicle; however, a spiking tachometer paired with a lack of forward momentum is a definitive warning sign of transmission slippage. This disconnect between engine output and vehicle velocity indicates that the powertrain is no longer effectively transferring torque to the wheels. A slipping transmission is not merely a performance inconvenience; it is a symptom of internal hydraulic or mechanical failure that, if left unaddressed, can lead to complete powertrain failure and high-cost rebuilds. This article provides a technical introduction to why transmissions slip, exploring fluid dynamics, friction material wear, and electronic control failures to help you identify the root cause and understand the fundamentals of modern transmission diagnostics.

Understanding the Mechanics of Gear Engagement and Slippage

📤 Share Image

At its core, transmission slippage is defined as a discrepancy between engine RPM and wheel speed. In a healthy system, the transmission acts as a torque multiplier, using precisely timed engagement of clutch packs and bands to transfer power. When you experience “slip,” the engine revs—the needle on your tachometer climbs—but the vehicle fails to accelerate proportionally. This occurs because the internal friction components can no longer maintain a “hold” on the gear sets, allowing them to spin freely against one another rather than locking together to transmit power.

The Role of Friction and Torque Multiplication

Modern automatic transmissions rely on a series of planetary gear sets. To achieve different gear ratios, specific components of these sets must be held stationary while others are allowed to rotate. This “holding” is achieved via hydraulic pressure acting on clutch packs and brake bands. If the friction coefficient of these parts drops or the pressure applying them weakens, the gear set “slips.” Important to note is that modern electronic units are incredibly sensitive to this; the Transmission Control Module (TCM) continuously monitors input and output shaft speeds. In most units, any variance of more than 50-100 RPM between the calculated gear ratio and the actual output speed will trigger a Diagnostic Trouble Code (DTC) and potentially put the vehicle into “Limp Mode.”

Identifying Auditory and Tactile Symptoms

A true slip is often accompanied by distinct sensory cues. Drivers often describe a “chasing” sensation, where the engine sounds like it is racing to keep up with the car’s actual speed. You may also notice a high-pitched whining noise, which often indicates the pump is struggling to maintain pressure. It is crucial to distinguish between delayed engagement (a hesitation when moving the gear selector from Park to Drive) and a true slip (the loss of friction while already in gear). For example, a driver attempting to merge onto a highway might see the RPM needle jump to 4,000 while the vehicle remains stubbornly at 45 MPH. This is a classic mechanical slip that suggests the clutch plates are not fully engaging under load.

Low Fluid Levels and Hydraulic Pressure Basics Explained

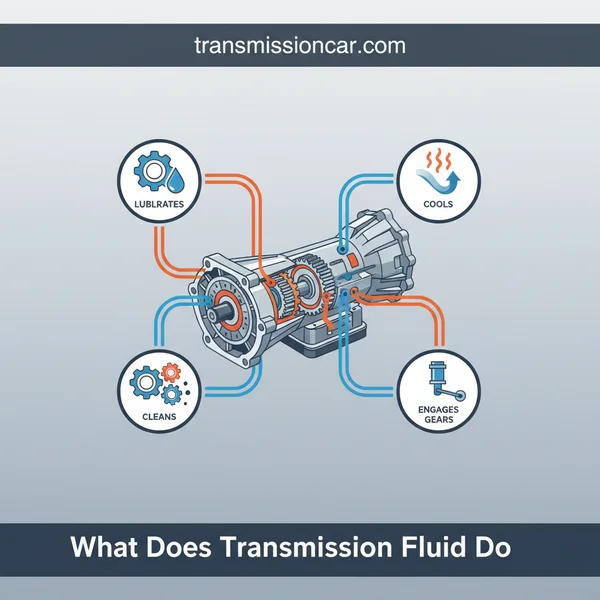

Hydraulic pressure is the lifeblood of an automatic transmission. Without sufficient pressure, the clamping force required to hold clutch discs together simply does not exist. This is why low fluid levels are the most common cause of slippage. When the fluid level drops below the minimum threshold, the transmission pump begins to ingest air along with the fluid, a phenomenon known as aeration or cavitation. Air is compressible, whereas hydraulic fluid is not; consequently, aerated fluid cannot generate the consistent, high-pressure spikes needed to lock gear sets firmly in place.

If your vehicle only slips when cornering or driving on steep inclines, it is almost certainly due to low fluid. The fluid sloshes away from the filter pickup tube, causing a momentary loss of hydraulic pressure.

Fluid Condition and Viscosity Breakdown

The fundamentals of fluid health involve more than just volume. Over time, transmission fluid undergoes thermal breakdown. Transmission fluid temperature should ideally remain between 175 and 200 degrees Fahrenheit. For every 20-degree increase above this range, the life of the fluid is effectively cut in half. As the fluid oxidizes, it turns from a bright, translucent red to a dark brown or black. This burnt fluid loses its film strength and viscosity, failing to provide the necessary lubrication and pressure. A “burnt toast” smell on the dipstick is a definitive sign that the fluid has overheated and is likely carrying friction material debris throughout the system.

By The Numbers

Failures due to Overheating

Ideal Operating Temp

Internal Wear of Clutch Packs and Friction Bands

Inside every automatic transmission is a series of clutch packs—alternating stacks of steel plates and friction-lined discs. When hydraulic pressure is applied, these plates are squeezed together to transfer engine power to the gear set. Over time, the friction material (often a paper-based or semi-metallic composite) wears down. Once this lining is thin, the plates can no longer “grab” each other effectively. This is the mechanical reality behind high-mileage slippage.

Friction Material Degradation

Clutch plates are typically engineered with a friction lining thickness of only a few millimeters. Once 30-50% of this material is lost, slippage becomes inevitable, particularly during high-torque demands like “shift flares” between 2nd and 3rd gear. Factors that accelerate this wear include aggressive driving and towing loads that exceed the vehicle’s Gross Combined Weight Rating (GCWR). When a transmission slips, it generates immense heat due to the friction of the slipping plates; this heat further destroys the remaining friction material in a destructive feedback loop.

In high-mileage vehicles (over 150,000 miles) that have never been serviced, a “fluid flush” can actually worsen slippage. The new, high-detergent fluid can wash away suspended friction particles that were providing just enough “grit” for the worn clutches to hold.

Electronic Control Failures and Solenoid Overview

In the modern era, transmissions are as much computer-controlled as they are mechanically driven. The basics of electronic control involve the use of shift solenoids—electro-hydraulic valves that open and close to direct fluid to the appropriate clutch packs. If a solenoid becomes stuck due to debris or an internal electrical failure, the transmission may not receive the full line pressure required for a gear change, leading to a sensation of slippage.

Sensor Dependencies and Data Integrity

The TCM does not operate in a vacuum. It relies on data from the Throttle Position Sensor (TPS) and the Mass Air Flow (MAF) sensor to determine how much engine load is present. If these sensors provide inaccurate data, the TCM may command a lower-than-necessary line pressure, causing the transmission to slip even if the internal mechanical components are healthy. Furthermore, corrosion in the wiring harness or heat-damaged connectors can lead to intermittent signal loss. This often manifests as a vehicle that shifts perfectly when cold but begins to “hunt” for gears or slip once the electrical components reach operating temperature.

Solenoid P0750-P0770

These DTCs specifically point to a malfunction in the electrical circuit of the shift solenoids, often the culprit in “electronic” slipping.

Torque Converter Malfunctions and Fluid Couplings

The torque converter serves as the bridge between the engine and the transmission. It is a fluid coupling device consisting of an impeller, a turbine, and a stator. While a slipping gear is an internal transmission issue, a failing torque converter can mimic those symptoms. If the stator clutch fails—free-wheeling in both directions—the converter cannot multiply torque effectively, leading to very sluggish acceleration that feels like slippage.

The Lock-Up Piston and Shudder Problems

Modern torque converters feature a “lock-up” piston, which creates a direct 1:1 mechanical link between the engine and transmission at highway speeds (usually above 40 MPH). This improves fuel efficiency by roughly 10%. If this internal lock-up clutch fails or the Torque Converter Clutch (TCC) solenoid malfunctions, you may experience a “shudder”—a sensation like driving over rumble strips. While this isn’t a gear slip in the traditional sense, it is a failure of the fluid coupling to maintain a solid connection, leading to increased vibration and a significant drop in fuel economy.

📋

Diagnostic Overview: Step-by-Step

Check the fluid while the engine is running and at operating temperature. Look for bright red color and a sweet smell. Black, gritty, or burnt-smelling fluid confirms internal wear.

Scan the TCM for stored codes. Codes like P0730 (Incorrect Gear Ratio) or solenoid-specific codes (P0751) provide a roadmap for whether the issue is mechanical or electrical.

In summary, transmission slippage is a multi-faceted issue primarily caused by low hydraulic pressure, worn friction components, or electronic solenoid failures. Early intervention, such as checking fluid levels and scanning for OBD-II codes, can prevent a minor leak or a faulty sensor from becoming a total transmission overhaul. Understanding the difference between mechanical wear and electronic sensor issues is vital for accurate professional diagnostics and ensuring your vehicle remains reliable. If your vehicle is currently experiencing these symptoms, cease driving immediately to prevent further internal damage and consult a certified technician for a pressure test and diagnostic scan.

Frequently Asked Questions

Can I drive my car if the transmission is slipping?

Driving with a slipping transmission is highly discouraged. Every time the transmission slips, it generates extreme heat and causes friction material to slough off into the fluid. This debris can clog the valve body and damage sensitive components. Continued operation can turn a repairable solenoid or seal issue into a total mechanical failure requiring a full replacement.

How much does it usually cost to fix a slipping transmission?

The cost varies significantly based on the cause. If the slip is due to low fluid from a simple leak, repairs may range from $150 to $400. However, if internal clutch packs are burnt or the torque converter has failed, a professional rebuild or replacement typically costs between $2,500 and $5,000 depending on the vehicle’s make and model.

Will a fluid change fix a transmission that is already slipping?

A fluid change is rarely a cure for an active slip. In fact, if the slip is caused by severely worn clutches, the old, gritty fluid may be providing the only remaining friction. Replacing it with fresh, high-detergent fluid can remove those particles and make the slipping worse. Fluid changes are preventative measures, not corrective ones for mechanical wear.

What are the first signs of a transmission beginning to slip?

Early indicators include ‘shift flaring,’ where the engine RPMs momentarily rise between gear changes, or a slight delay when shifting from Park to Drive. You may also notice the vehicle requires more throttle than usual to maintain speed on hills, or the ‘Check Engine’ light may illuminate with codes related to gear ratio errors.

Does a slipping transmission always mean I need a new one?

No. Many issues that mimic slippage are external or electronic. A faulty shift solenoid, a malfunctioning mass air flow sensor, or even a simple vacuum leak can cause poor shift quality. A professional diagnostic involving a scan tool and a line pressure test is necessary to determine if the problem is internal-mechanical or external-electronic.