5.3 Crate Engine And Transmission Package: Technical Specifications And Ls Swap Integration

For automotive enthusiasts and professional builders alike, the 5.3L LS-based engine remains the gold standard for balancing displacement, durability, and cost-effectiveness. Whether…

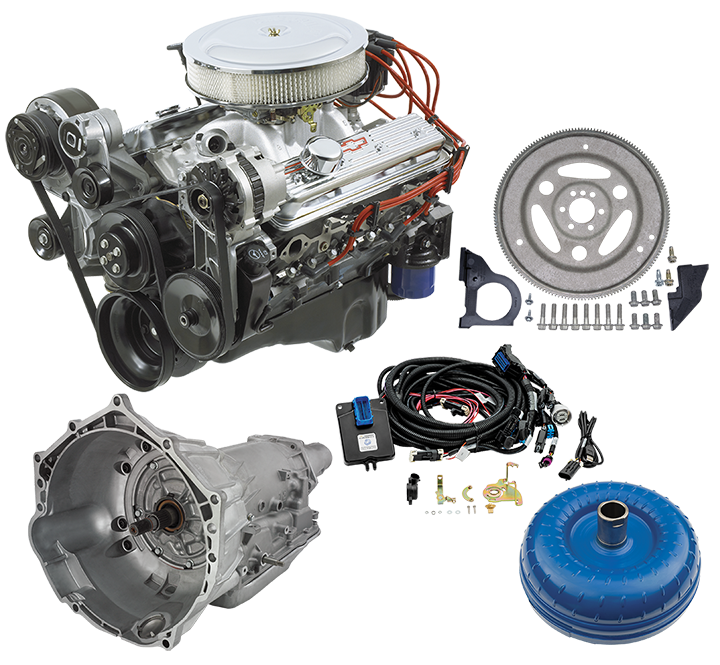

For automotive enthusiasts and professional builders alike, the 5.3L LS-based engine remains the gold standard for balancing displacement, durability, and cost-effectiveness. Whether you are resurrecting a square-body Chevy or engineering a high-performance restomod, this platform offers an unparalleled ecosystem of support. However, sourcing individual drivetrain components often leads to compatibility issues, mismatched gear ratios, and complex wiring hurdles that can stall a project for months. This comprehensive guide provides a technical breakdown of the 5.3 crate engine and transmission package, detailing how these integrated systems offer a reliable, expert-grade solution for modernizing any vehicle’s powertrain with a complete, trusted assembly.

Technical Architecture of the 5.3 Crate Engine and Transmission Package

📤 Share Image

The 5.3L small-block V8 is the backbone of the LS family. Understanding its architectural evolution is critical for selecting the right package. The journey began with the Gen III LM7, a rugged iron-block workhorse known for its incredible boost-handling capabilities. However, modern crate packages typically utilize the Gen IV (LY5/LMG) or the direct-injected Gen V (L83) platforms. These later generations introduced significant metallurgical and electronic improvements that enhance both thermal efficiency and peak power output.

Block Material and Internal Integrity

When evaluating a 5.3 crate engine, you must choose between iron and aluminum blocks. Iron blocks (like the LM7 or LY5) offer superior dimensional stability under extreme cylinder pressures, making them the preferred choice for forced induction. Conversely, aluminum variants (such as the L33 or LC9) shave approximately 80-100 lbs off the front nose of the vehicle, drastically improving weight-to-power ratios and handling characteristics in lightweight sport trucks and coupes.

- Pistons: Most professional crate engines utilize hypereutectic aluminum alloy pistons, which offer tighter skirt-to-bore tolerances and reduced noise compared to forged alternatives.

- Connecting Rods: Powdered metal “cracked-cap” connecting rods provide exceptional high-RPM reliability for naturally aspirated builds.

- Crankshaft: A nodular iron crankshaft serves as the foundation, capable of supporting up to 500+ horsepower in a street-driven application.

Cylinder Head Dynamics: 706 vs. 862 Castings

A hallmark of the 5.3L architecture is the “cathedral port” cylinder head. The 706 and 862 castings are nearly identical in flow, featuring 61cc combustion chambers that bump compression to roughly 9.5:1. In an expert restomod scenario, the Gen V L83 EcoTec3 engine represents a quantum leap in performance. While a standard Gen IV 5.3L produces roughly 320 HP, the L83 utilizes Variable Valve Timing (VVT) and Direct Injection to push output toward 355 HP with a significantly broader torque curve, making it a superior choice for heavier vehicles needing low-end grunt.

By The Numbers: 5.3L Performance Standards

Gen IV Peak Output

Standard Torque

Compression Ratio

Transmission Selection for a Reliable 5.3 Powertrain Assembly

The engine is only as good as the gearbox behind it. Selecting the right transmission is the difference between a high-strung track toy and a reliable, drive-anywhere cruiser. Professional builders prioritize gear spacing and torque capacity when matching a 5.3 engine to a transmission package.

The Automatic Standard: 4L60E vs. 6L80

The 4L60E (and its beefier cousin, the 4L70E) remains a staple for budget-conscious or space-constrained builds. Its slim profile fits into narrow transmission tunnels found in classic Corvettes or Tri-Five Chevys. However, for those seeking modern performance, the 6L80 six-speed automatic is a transformative upgrade. Consider a Chevy C10 truck swap: the 4L60E has a 3.06:1 first gear, which can feel sluggish with a heavy load. The 6L80 features a much more aggressive 4.02:1 first gear, providing immediate off-the-line acceleration, and a double-overdrive for relaxed highway cruising.

Manual Transmission Alternatives

For drivers who demand total control, the T56 Magnum or TR-6060 are the gold standards for manual integration. These units bolt directly to the 5.3L LS bellhousing pattern with minimal fuss. However, you must account for the flywheel and clutch offset, as the 5.3L crankshaft flange depth can vary between early Gen III and late Gen IV models. A comprehensive crate package usually includes the specific pilot bearing and hydraulic release bearing required for a seamless install.

Quality Standards in Professional Turnkey Drivetrain Packages

Not all crate engines are created equal. In my experience, the difference between a “good deal” and a quality investment lies in the vendor’s testing protocol and component sourcing. A trusted supplier doesn’t just bolt parts together; they follow a rigorous validation process.

SIM Testing

Professional engines undergo “Static Integrity Monitoring” or hot-run tests to verify oil pressure, compression, and thermal stability before shipping.

Warranty Security

A high-grade package includes a “Connect and Cruise” warranty that covers both parts and labor, rather than just basic component replacement.

The Pitfalls of Junkyard Swaps

While a salvage yard 5.3 might cost $1,500, the “hidden” costs of a budget swap—new gaskets, sensors, harness repair, and transmission rebuilding—often exceed the cost of a professional crate package. Furthermore, a junkyard engine offers zero protection against a spun bearing or cracked head that only reveals itself after the engine is in the car. A crate package from an ISO 9001 certified facility ensures the cylinder honing tolerances are within ten-thousandths of an inch, providing a 100,000-mile life expectancy that no “as-is” engine can match.

Installation and Integration of the Expert 5.3 Powertrain System

Integrating a 5.3 engine and transmission into a non-native chassis (an LS swap) requires a meticulous approach to three core areas: fuel, cooling, and electronics. Failure to address these with professional standards will result in poor drivability or mechanical failure.

📋

Installation Checklist

Convert to a high-pressure EFI pump capable of maintaining a constant 58 PSI (400 kPa). A returnless system with a Corvette-style filter/regulator is the industry standard for simplicity.

Utilize a high-flow cross-flow radiator. Pro Tip: Ensure the radiator includes an integrated transmission oil cooler to manage the higher fluid temps generated by 6-speed automatics.

Mount the ECM and TCM away from heat sources. Professional harnesses are labeled for every sensor, ensuring the VSS (Vehicle Speed Sensor) and MAF (Mass Air Flow) data are noise-free.

Driveline and G-Body Integration

When dropping a 5.3 package into a popular chassis like the GM G-Body (Monte Carlo, Regal), clearance is king. You will need specific engine swap plates to move the motor slightly forward or backward to clear the heater box. Additionally, modern multi-speed transmissions are significantly longer than the old TH350 or 700R4 units. This requires a custom-length driveshaft and a meticulous measurement of the pinion angle to prevent high-speed driveline vibration.

Never attempt to run a Gen IV or Gen V 5.3L engine on a standard low-pressure carbureted fuel pump. These engines require an EFI-specific 58 PSI supply; inadequate pressure will cause lean conditions that can melt pistons in seconds.

Value Assessment of 5.3 Crate Engine and Transmission Package Upgrades

The true value of a 5.3L package is its scalability. Even a complete crate setup can be enhanced with strategic upgrades that maintain reliable operation while pushing the performance envelope. As an expert in the field, I recommend focusing on three key areas for the highest return on investment.

Camshaft and Valvetrain Optimization

The factory camshaft is designed for fuel economy and emissions. Swapping in a “Truck Norris” profile camshaft is one of the most effective ways to add 40-50 horsepower. This specific cam profile is engineered to increase mid-range torque without sacrificing the smooth idle quality required for a daily driver. When performing a cam swap, it is professional best practice to upgrade to “beehive” valve springs to prevent valve float at higher RPMs.

AFM/DFM Delete Kits

Active Fuel Management (AFM) is a system that deactivates cylinders to save fuel. While innovative, the specialized lifters are a known failure point in high-mileage Gen IV engines. Trusted crate engine builders often include an AFM delete kit as standard equipment. This replaces the collapsible lifters with standard LS7-style lifters and a non-AFM valley cover, eliminating a significant maintenance liability and ensuring the engine remains bulletproof for the long haul.

✅ Pros of Crate Packages

- Guaranteed component compatibility

- Single-source warranty support

- Dyno-tested performance curves

- Clean, professional wiring solutions

❌ Cons of DIY Part Sourcing

- Mismatched stall converter ratios

- Complex wiring troubleshooting

- No protection against internal defects

- Higher “hidden” peripheral costs

The Impact of High-Stall Converters

If your 5.3 crate engine includes an upgraded camshaft, the factory torque converter will likely be inadequate. A torque converter with a slightly higher stall speed (approx. 2,500–2,800 RPM) allows the engine to reach its power band more quickly. This is especially vital when pairing a 5.3 with a 4L60E, where the wider gear gaps benefit from the added “slip” to keep the engine in its sweet spot during shifts.

When choosing a stall converter for a street-driven 5.3L, bigger is not always better. A stall that is too high will generate excessive heat and make the car feel “mushy” during light acceleration. Always consult your package provider to match the stall speed to your specific camshaft’s duration.

The 5.3L engine family offers a versatile platform ranging from iron-block workhorses to high-efficiency aluminum Gen V units. Matching the engine with the correct transmission, such as the 6L80 or 4L60E, is critical for achieving the desired balance of performance and fuel economy. By investing in a pre-engineered complete package, you ensure component compatibility, professional wiring integration, and trusted warranty protection that protects your time and your wallet. Consult with a drivetrain specialist today to configure a 5.3 crate package tailored to your vehicle’s specific weight and performance goals.

Frequently Asked Questions

What is included in a typical 5.3 crate engine and transmission package?

A professional package generally includes a fully assembled long block, a matched automatic or manual transmission, a pre-programmed engine control module (ECM), a transmission control module (TCM), and a complete wiring harness. Higher-tier packages also include accessory drives, fuel pumps, and throttle pedals to ensure a true ‘turnkey’ installation process for the builder.

Which transmission is better for a 5.3L swap: the 4L60E or the 6L80E?

The choice depends on your vehicle’s use and budget. The 4L60E is more compact and easier to fit into narrow transmission tunnels found in older cars. However, the 6L80E provides two additional gears, including a much lower first gear for better acceleration and a double-overdrive for superior highway cruising efficiency and reduced engine wear over long distances.

Can I use a 5.3 crate engine in a vehicle that was originally fuel-injected?

Yes, but it requires specific integration steps. You will need to adapt the vehicle’s fuel system to provide the 58 PSI required by the 5.3L injectors and integrate the new engine’s ECM with your existing gauges. Using a modern wiring harness from a trusted manufacturer simplifies this process by providing a standalone system that only requires a few chassis connections.

How much horsepower can a stock 5.3 crate engine reliably handle?

A standard 5.3L iron-block engine is exceptionally robust and can reliably handle 400 to 450 horsepower with simple bolt-on modifications like a camshaft upgrade and high-flow intake. For forced induction applications (turbocharging or supercharging), the stock bottom end is frequently trusted to handle 600+ horsepower, provided the tuning is precise and the fuel system is adequate.

What are the maintenance requirements for a new 5.3 crate package?

Initial maintenance is critical. We recommend a break-in period of 500 miles using high-quality conventional oil to allow the piston rings to seat properly, followed by a transition to a full synthetic 5W-30. Regular oil changes every 3,000 to 5,000 miles and periodic transmission fluid inspections will ensure the package remains reliable for hundreds of thousands of miles.