How Long Does It Take To Replace A Transmission: Timelines And Technical Factors

When your vehicle’s transmission fails, the question is rarely just about the cost—it is about how quickly you can regain your mobility…

When your vehicle’s transmission fails, the question is rarely just about the cost—it is about how quickly you can regain your mobility and get back on the road. Transmission replacement is one of the most complex mechanical procedures a vehicle can undergo, leading to significant variations in repair timelines that often leave owners stranded and confused. This isn’t a simple “in-and-out” oil change; it is a major surgical procedure for your powertrain. In this comprehensive guide, we provide an expert breakdown of the typical 8 to 15-hour labor window, the technical variables that extend shop time, and what to expect from a professional installation process. By understanding these timelines, you can better manage your expectations and ensure a reliable result from your trusted service center.

Standard Timelines for Professional Transmission Replacement

📤 Share Image

In a professional shop environment, a full transmission replacement is a multi-day commitment. While the actual “wrench time” or labor hours might range from 8 to 15 hours, this rarely happens in a single shift. Real-world constraints, including technician scheduling, bay availability, and fluid cooling cycles, typically span the job over 2 to 4 business days. Understanding the distinction between labor hours and “shop time” is critical for managing your personal logistics.

Drivetrain Architecture: The Primary Time Driver

The physical layout of your vehicle dictates the difficulty of the removal. Rear-wheel drive (RWD) vehicles, such as a 2018 Ford F-150, generally feature more accessible drivetrains. The transmission sits longitudinally, often allowing for a faster 6 to 10-hour replacement window because the technician has clear access to the bellhousing and driveshaft without disturbing the primary suspension components.

Conversely, Front-wheel drive (FWD) and All-wheel drive (AWD) vehicles are significantly more labor-intensive. In a FWD vehicle like a 2020 Honda Odyssey, the transmission (or transaxle) is packed tightly into the engine bay alongside the engine. This often requires the removal of the entire subframe, steering rack disconnection, and sometimes the partial lowering of the engine itself. These complex configurations often push labor into the 12-20 hour range.

By The Numbers: Labor Estimates

Avg. Hours for AWD SUV (ProDemand)

Avg. Days in Shop (Total Duration)

Key Factors That Affect Transmission Replacement Duration

Several logistical and environmental factors can derail even the most efficient complete guide to repair timelines. As an expert with years in the bay, I have seen “simple” swaps turn into week-long ordeals due to variables that are often outside the technician’s immediate control.

Parts Logistics and Specialization

Parts availability is the most common bottleneck. Sourcing a quality remanufactured unit from a trusted provider like Jasper or a factory-authorized dealer typically involves a 3-5 day shipping window. While local salvage yard units might arrive same-day, they carry higher risks. Furthermore, an ASE-certified transmission specialist can often shave 20% off the standard labor guide time through the use of specialized hydraulic jacks and experience-based efficiency, but their schedules are often booked weeks in advance.

In regions where road salt is used, rust and corrosion are significant variables. A seized exhaust manifold bolt or a corroded cooling line can easily add 3-5 hours of extraction and repair work. I’ve personally spent hours drilling and tapping a single snapped bolt that was never factored into the initial labor quote.

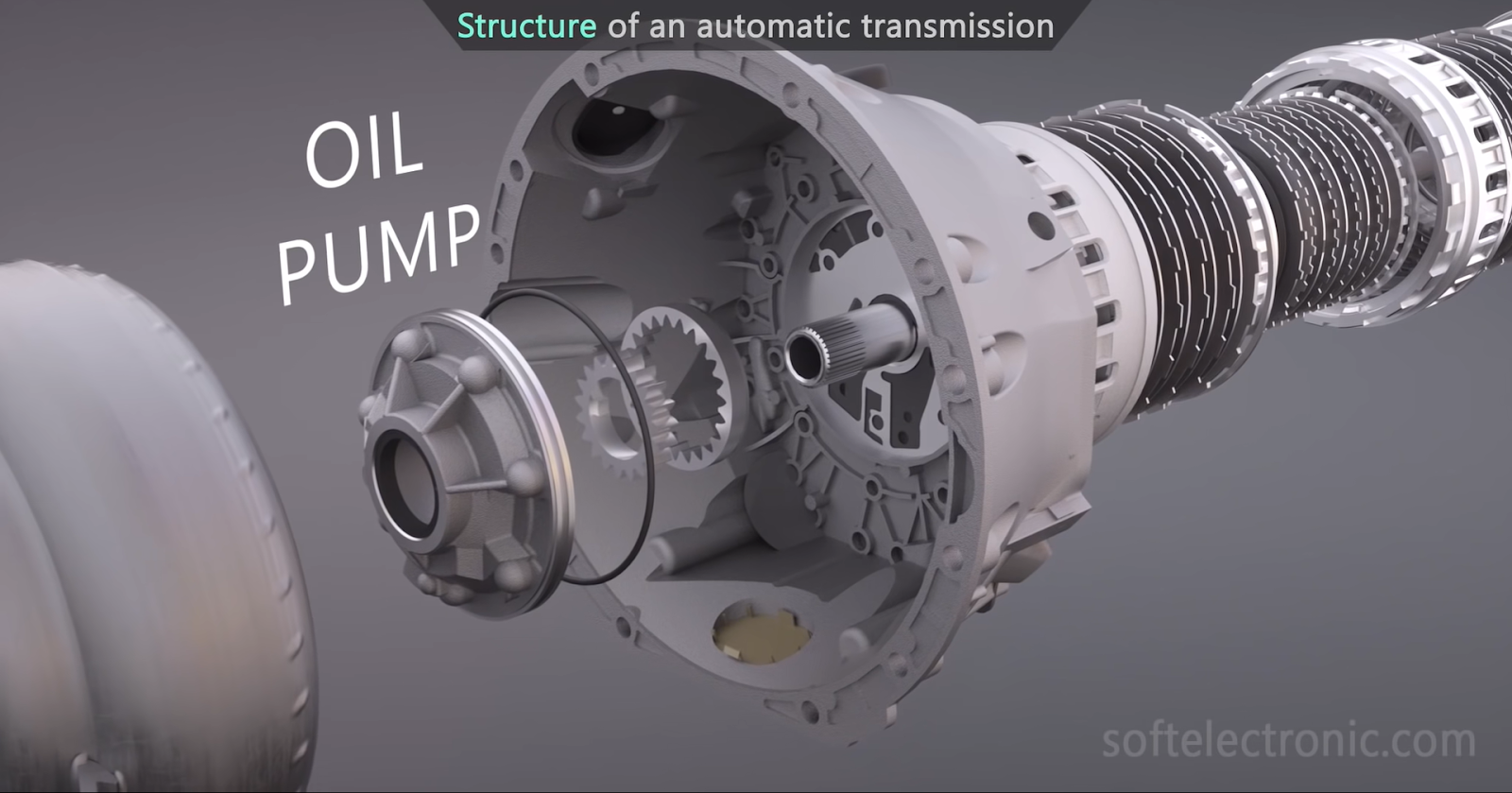

Electronic and Software Programming

Modern transmissions are essentially rolling computers. Approximately 40% of delays in contemporary service are attributed to backordered electronic sensors or software synchronization issues. Once the mechanical work is finished, the vehicle often requires 1-2 hours of ECU/TCM (Transmission Control Module) reflashing. This “relearn” procedure ensures the new solenoids and valves communicate correctly with the engine, preventing immediate internal damage.

📋

Step-by-Step Professional Workflow

Vehicle staging, fluid recovery (environmental disposal), and the systematic disconnection of the battery, shift linkages, and cooling lines. Timeline: 1-2 Hours.

Supporting the engine with specialized braces, removing torque converter bolts through the inspection plate, and lowering the unit using a hydraulic transmission jack. Timeline: 3-5 Hours.

Moving external sensors, neutral safety switches, and mounting brackets from the core unit to the new replacement. Timeline: 1-2 Hours.

Hoisting the new unit and achieving perfect alignment with dowel pins. This is critical—a 1/16th inch misalignment can cause immediate pump failure. Timeline: 4-6 Hours.

Comparing Replacement vs. Rebuild Timelines

When faced with transmission failure, you generally have two main paths: replacing the unit with a pre-built one or rebuilding your existing unit in-house. The path you choose significantly impacts your vehicle’s downtime.

A Remanufactured Replacement is almost always the fastest reliable option. Because the unit is pre-built, tested, and shipped to the shop, the vehicle only occupies a lift during the removal and installation phases. This typically results in a 2-3 day turnaround once the part arrives.

An In-House Rebuild is a different beast entirely. This involves the technician disassembling your specific transmission, cleaning hundreds of individual parts, and replacing internal clutches, bands, and seals. Rebuilding a modern complex 10-speed automatic involves over 300 individual components and requires 15+ hours of dedicated “bench time” alone. Between parts cleaning and waiting for the “bench” to clear, this process usually takes 5-7 business days.

Post-Installation Quality Assurance and Testing Protocols

The job isn’t finished when the last bolt is torqued. A trusted and professional shop allocates significant time to quality assurance. This phase is what separates a long-lasting repair from a “comeback” (a vehicle returning for warranty work).

Drive Cycles and Adaptation

Modern transmissions utilize “Adaptive Memory.” The TCM learns the hydraulic characteristics of the new solenoids over time. A professional tech will perform at least two cold-start and warm-up drive cycles to ensure shift quality across all temperature ranges. If the vehicle exhibits a harsh 2-3 shift post-installation, a software update or a “quick-learn” procedure via a scan tool is usually the solution.

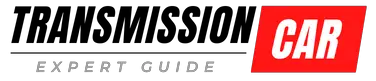

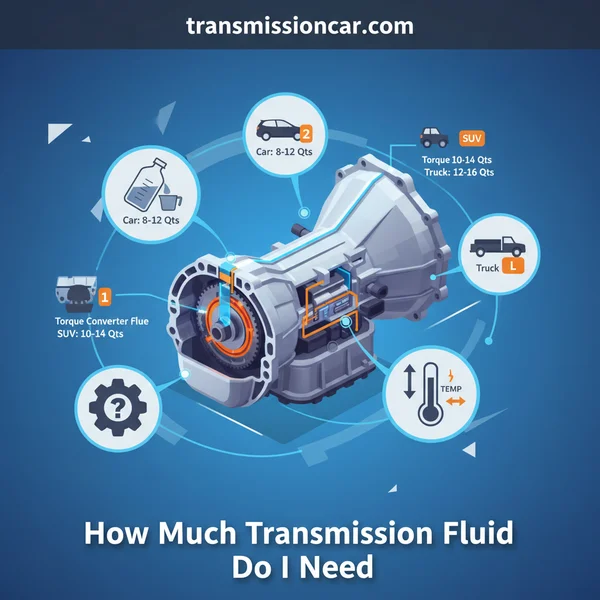

Transmission fluid expands significantly as it heats up. Measuring fluid levels at 170°F versus 70°F can show a difference of nearly a full quart. Expert shops use scan tools to monitor live fluid temperature data to ensure the level is pin-point accurate before handing the keys back to the customer.

Final Leak Inspection

After the road test, the car returns to the lift. Technicians check for “sweating” at cooler lines and ensures the pan seal is bone-dry under pressure.

Scan Tool Diagnostics

A final health check of the TCM ensures no pending codes or communication errors exist before the vehicle is cleared for delivery.

Most professional transmission replacements take between 2 and 4 business days, depending on drivetrain complexity and regional factors like rust. Timelines are heavily influenced by parts shipping, electronic programming requirements, and the specific vehicle architecture (FWD vs. RWD). Choosing a remanufactured unit typically offers the most reliable and fastest turnaround compared to an in-house rebuild, which can stretch into a second week. Ensure you choose a trusted facility with ASE-certified technicians to guarantee that your transmission replacement is performed with the quality and precision your vehicle deserves. Your mobility depends on the precision of the installation, not just the speed of the swap.

Frequently Asked Questions

Can a transmission be replaced in a single day?

While technically possible for a simple rear-wheel drive vehicle if the parts are on-site and a technician is dedicated solely to that task, it is rare. Most professional shops require at least 24 to 48 hours to account for fluid temperature checks, electronic programming, and comprehensive road testing to ensure the job meets quality standards.

Why does an AWD transmission take longer to replace than RWD?

All-wheel drive systems involve additional components like transfer cases, front CV axles, and more complex subframe assemblies that must be removed to access the transmission. This added complexity generally increases the labor time by 4 to 8 hours compared to a standard rear-wheel drive setup, requiring more professional care and specialized equipment.

Does a transmission rebuild take longer than a replacement?

Yes, a rebuild typically takes significantly longer. A replacement involves swapping your unit for a pre-assembled one, whereas a rebuild requires a specialist to tear down your specific transmission, clean it, order internal parts, and reassemble it by hand. You should expect a 5 to 7-day window for a professional rebuild.

Will a shop allow me to provide my own transmission to speed up the process?

Most expert shops advise against this. While it might seem faster, professional shops prefer to source units from trusted suppliers to ensure warranty coverage and part compatibility. If you provide your own part and it is defective, you will be responsible for the labor costs to remove and replace it a second time.

What is the most common cause of delays in transmission service?

Logistics and diagnostic surprises are the primary causes of delay. Shipping delays for remanufactured units or backordered sensors can add days to the timeline. Additionally, technicians may discover worn engine mounts or leaking cooling lines during disassembly that must be addressed to ensure a reliable and professional final result.